What Is a CNC Machine?

A Complete Guide

Why do you need a HALOONG CNC in your factory?

From traditional handicrafts to semi-automation and now to automated production, CNC machinery has become more important in industrial production. From handicraft enthusiasts to small workshops and even large factories, people use CNC machinery to manufacture various parts to complete the final work. So what is a CNC machine tool? What is its development history? How does it work? In which industries can it be used? You can learn all the content according to our introduction.

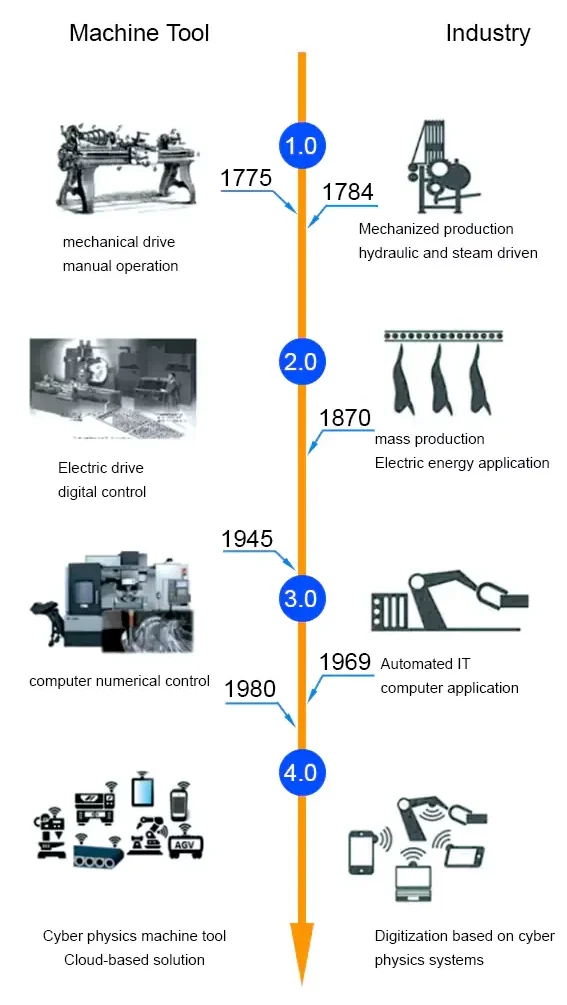

The History Of CNC Machine

In the mid-twentieth century, engineers used punched paper tape to control the first CNC machine tools, which had an accuracy of 0.1 mm, but were very expensive.

The turning point came in 1971, when microprocessors reduced control system costs by 70 percent. Three-axis machine tools quickly became popular, with 200,000 new machines added to factories around the world within a decade.At the beginning of the new century, the three-dimensional models designed by CAD software were directly converted into tool paths through the CAM system, with the error controlled within 3 microns (1/25 of a hair). The precision gear processing of watches, which originally took a month, was shortened to 8 hours.

As a major manufacturer and seller, China continues to break through processing limits while leveraging the advantages of the industrial chain to produce more reliable and cost-effective machines to meet the needs of individual enthusiasts, small workshops and high-end manufacturing factories.The popularity of CNC equipment has made industrial products cheaper and cheaper, and they can be accepted and used by more people. CNC equipment is changing people's lives.

What Is CNC?

CNC is a precision machining system controlled by a computer program. uses CAD and CAM computer-aided design and simulation,which can automatically complete manufacturing processes such as cutting, engraving, and drilling. After the operator inputs digital instructions, the equipment drives the tool to accurately process materials such as metal, wood or plastic, realizing mass production of complex parts. It is widely used in aerospace, automobile manufacturing, electronic components and other fields, and is the core production equipment of modern smart factories.

According to the latest industry white paper data, CNC technology has penetrated into 89% of discrete manufacturing fields, among which there has been explosive growth in the field of wood material processing. It can complete the processing of wood such as plywood (including blockboard, multilayer board, etc.), particleboard (including OSB board, etc.), fiberboard (including MDF/HDF board, hardboard, other fiberboard, etc.).

How Does A CNC Machine Work?

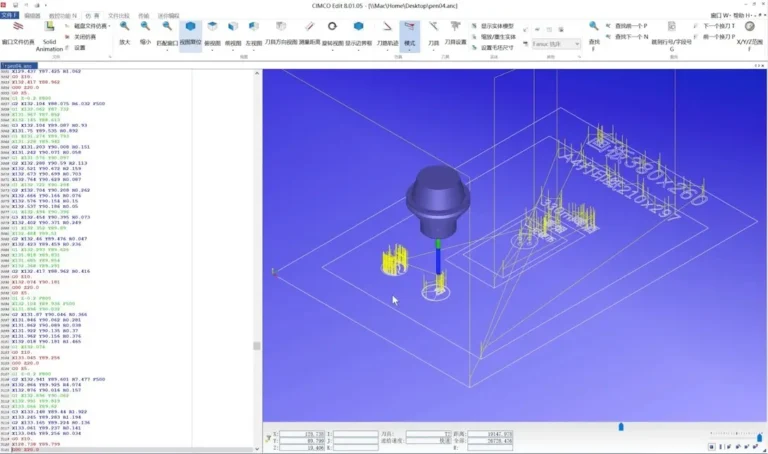

Unlike other processing methods, CNC processing requires the use of CAD/CAM computer-aided design and simulation programming. After the operator inputs the G/M code obtained by computer programming into the equipment, the equipment will automatically drive the tool for precise processing.

Although it sounds simple, this process requires different computer software to assist your work. These software make the steps that originally required complex processes much easier, can show the outline of your expected product in a graphical form, and simulate the processing process so that you can predict possible errors in advance. It can greatly reduce part defects and raw material waste.

Computer-Aided Drawing (CAD)

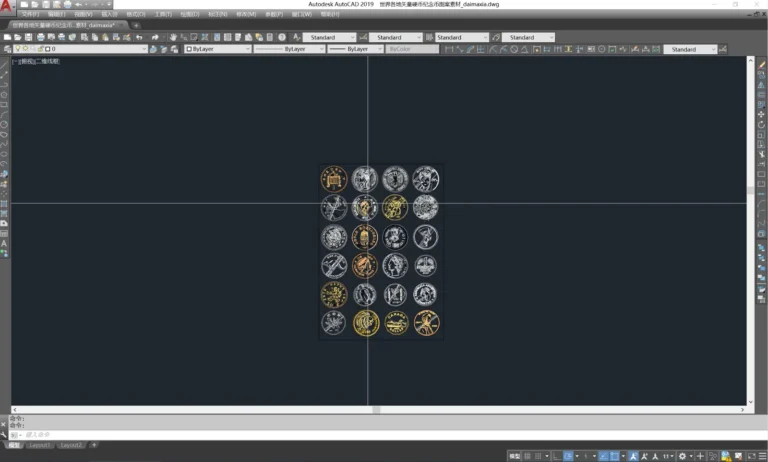

Computer-aided design (CAD) is the use of computer programs to create, modify, and analyze 2D or 3D graphical representations of physical objects, replacing manual sketches and product prototypes. There are many CAD software, such as AUTODESK CAD and others. CAD is widely used in computer automation and media special effects as well as product and industrial design. They can be integrated with computer-aided manufacturing (CAM) software to fully display the entire product processing process.

Computer-Aided Manufacturing (CAM)

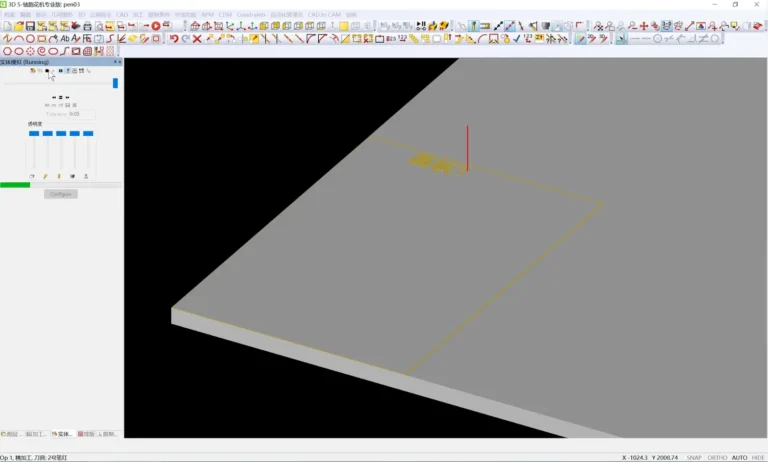

CAM software is Computer-Aided Manufacturing software, which is a tool used to assist the design and production process in the manufacturing industry. CAM software simulates the actual processing process through algorithms. There are also many well-known software, such as ALPHACAM and others, which can convert design models into machine-understandable instructions, such as G or M codes, to control the equipment for actual manufacturing operations.

CNC Structure: What Are The Parts Of A CNC Machine

There are many types of CNC machines to choose from, each with different uses, such as CNC lathes, CNC milling machines, and CNC engraving machines. Similar to CNC woodworking engraving machines, most of them contain the following components.

Controller

Body

Vacuum Adsorption Table

Spindle

Gantry

Drive system

What Makes CNC So Popular?

Everyone has different reasons for choosing CNC, but the most important reasons may be two points.First, CNC can produce more efficiently. The efficiency of CNC can be attributed to automatic processing and nested manufacturing. In particular, the repetitive processing method of batch products,which greatly improves efficiency. Another point is that nested production of materials can be achieved. For example, in the manufacturing process of panel furniture, engineers produce specific parts groups from flat materials (such as wood or plastic boards). With the help of computer design and manufacturing, suitable parts are nested together to maximize the number of components that can be processed using a single piece of material and reduce waste. Therefore, CNC is a more environmentally friendly manufacturing method.

Second, CNC can achieve more accurate processing. The original intention of inventing CNC machines is to achieve reproducible fine processing that humans cannot do, especially for the fields of automobiles, aerospace, semiconductors, etc. Similarly, in the field of woodworking, using CNC equipment to produce parts can make your final work more perfect.

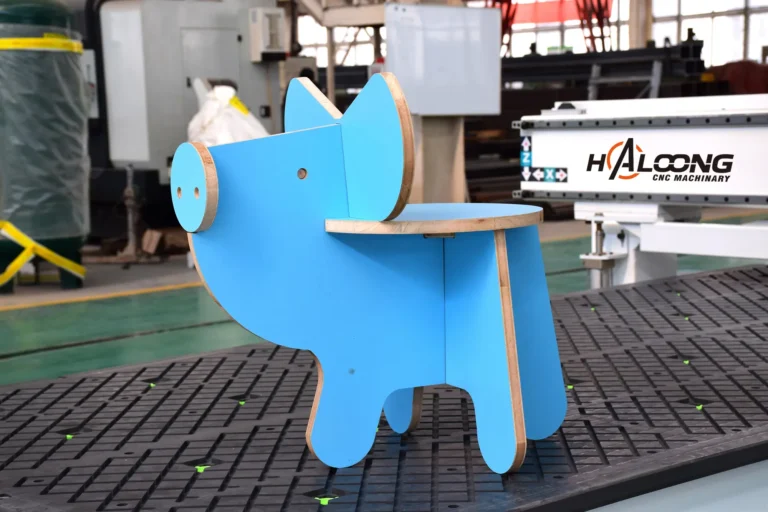

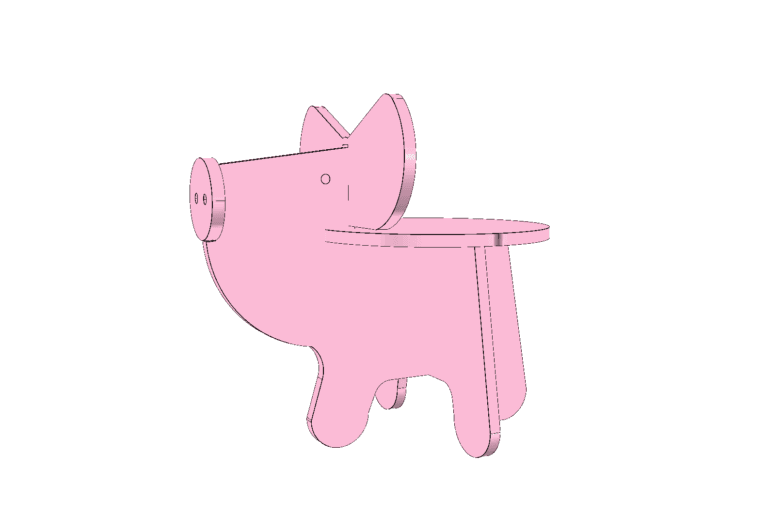

What Can I Do With A CNC Machine?

CNC machines can be used in many industries. We recommend that you choose the right CNC equipment according to the industry you are in and the materials you need to process. HALOONG has a rich product line in the field of CNC woodworking machinery, which means there is always a machine suitable for your application. We will introduce them separately, and you can consider which CNC is right for you.

Multiple Spindles Cutter Head Milling And Drilling Machine

With four high-performance spindles, it can clamp a variety of tools at the same time, such as contour milling tools, drilling tools, grooving tools, and 3D engraving tools of different diameters. For typical materials (such as OSB), it can achieve 10,000-15,000 mm/min of load processing movement and 400,000-500,000 mm/min of no-load movement. It is suitable for mass production of parts with fixed processing procedures.

Linear Tool Magazine Automatic Tool Change Spindle Machine

The high-performance spindle has a higher speed than other machines, and the linear tool magazine can realize automatic tool change. The tool magazine is equipped with 12-16 tools. It can clamp more tools than other machines, such as contour milling cutters, drilling cutters, grooving cutters and 3D engraving cutters of different diameters. For typical materials (such as OSB), it can achieve 12,000-18,000 mm/min of load processing and 450,000-600,000 mm/min of no-load movement. It is more suitable for the manufacture of parts with a single processing method that requires rapid production, and the manufacture of parts with multiple composite processing methods that do not pursue processing speed.

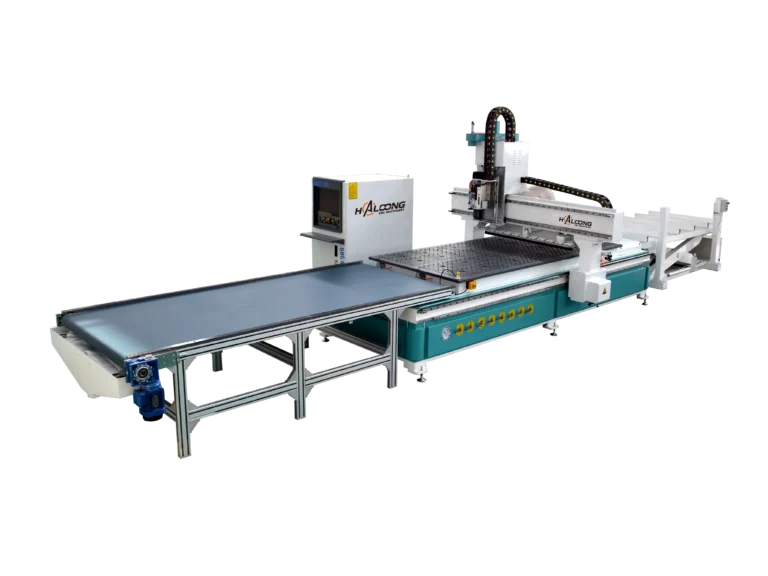

Automatic Loading Machine With Lif And Conveyor Belt

The tail is equipped with a lift that can bear a load of 1-3 tons and is used to support large quantities of plates without manual handling. The front is equipped with a conveyor belt to transport the processed parts to the sorting area. The main machine can be equipped with a four-spindle tool head machine and a linear tool magazine automatic tool changer. These machines have an additional vacuum adsorption loading function to achieve uninterrupted processing. This is the best choice for customers who pursue cost-effective automated production.

Drilling And Slotting Machines For Machining Side Areas

With two spindles, different tools can be installed for side milling, slotting and drilling. With the laser sensor, it can accurately determine the location where slotting and drilling are required for automatic processing. You can also customize the processing area to achieve a more flexible processing method.

What Is The Price Of CNC Machines?

When you consider buying a CNC machine to help your business better, one question that makes you hesitate is the price of the CNC. Usually the function and configuration of the machine will determine its price.

But the good news is that we are a professional CNC machine manufacturer from China. As you know, China has a huge supply chain advantage. We can make machines with a higher cost performance. The quality and performance are comparable to those expensive machines. And we can provide better purchase consultation and after-sales service.

We hope that every user can enjoy the efficiency improvement and business improvement brought by CNC machines, so we have a wide range of products. Some CNC machines are designed for small workshops that purchase for the first time, and are also suitable for skilled craft production enthusiasts. These machines usually cost several thousand dollars. Many machines are suitable for medium and large factories that want to increase production and standards, and the price is tens of thousands of dollars. For specific prices, please contact our CNC experts and we will quote you according to your needs.

For those who want customized functions, we can provide OEM service, the price is based on different configurations.