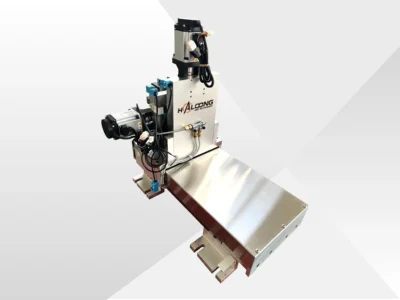

PUR Glue Machine Kit For Edge Bander

Category:

Model:

Specs & Details:

- Unmatched Bond Strength

- Eco-Friendly & Efficiency, Precise Dispensing

- Dual-Outlet Hose, Differentiate glue colors

Price Range :

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

Why the HALOONG PUR Glue Machine Stands Out

Pur glue machine can replace the traditional edge banding machine EVA glue machine. This polyurethane reactive (PUR) hot melt system delivers superior bonding for woodworking, furniture assembly, and more. The HALOONG PUR Glue Machine is your go-to solution for precision, durability, and efficiency in industrial adhesive applications.

Unmatched Bond Strength:

- Unlike EVA edge banding, which uses traditional hot melt glue prone to heat and moisture degradation, our moisture-curing PUR adhesive creates permanent, high-strength bonds that endure extreme conditions.

Versus Laser Edge Banding:

- While laser edge banding offers seamless aesthetics, it requires costly equipment and lacks the versatility of our PUR system, which excels across wood, and composites.

Eco-Friendly & Efficiency:

- This solvent-free, energy-efficient design reduces costs and outpacing EVA’s higher waste profile.

User-Friendly Features:

- With an intuitive PLC controller and dual Teflon-coated tank to prevent glue buildup, cleanup is a breeze compared to sticky EVA residue.

High-Speed Precision:

- Adjustable temperature and dispensing speed outshine laser systems’ fixed setups, boosting output without sacrificing quality.

Double glue bucket configuration:

- Double glue buckets and double hoses are used to dispense glue. Different glue colors can be distinguished according to the color of the board and edge banding to achieve a perfect matching effect.

Technical Specifications

| Feature | Details |

| Glue Tank Capacity | 20L (5 Gallon) |

| Temperature Range | 125°C – 180°C (257°F – 356°F) |

| Power Consumption | 5 kW (7 HP) |

| Dimensions | 1065 x 750 x 1700 mm |

| Glue Type | PUR Hot Melt (Moisture-Curing) |

| Feed System | Double glue buckets and double hoses are used to dispense glue, Precise Dispensing |

| Weight | 250 kg (550 lbs) |

| Form Factor | Square (Linear option available) |

Key Applications

Woodworking:

- Outperforms EVA in edge banding and profile wrapping on MDF, plywood, and solid wood with flawless durability.

Furniture Manufacturing:

- Bonds laminates and veneers stronger than laser methods, ideal for high-end finishes.

Construction Materials:

- Perfect for SIPs and composites, offering flexibility beyond laser limitations.

Advantages Over EVA and Laser Edge Banding

Compared to EVA edge banding, our PUR hot melt glue solution resists heat, moisture, and wear, ensuring long-lasting results without the mess. Laser edge banding shines for aesthetics but demands expensive setups and lacks the adaptability of our PUR adhesive machine, which uses a dual-outlet hose for precise dispensing across diverse projects. With measurements in metric and imperial units (e.g., 250 kg/550 lbs).The compact design and self-cleaning tank further enhance usability, keeping your workflow smooth and efficient.

Ready to Elevate your edge banding? The HALOONG PUR Glue Machine is the industrial bonding equipment trusted by manufacturers worldwide. Contact us for a quote or demo and see why it’s the smart choice over EVA and laser alternatives.

Searching for the ultimate PUR glue machine to transform your production line?

Pur glue machine can replace the traditional edge banding machine EVA glue machine. This polyurethane reactive (PUR) hot melt system delivers superior bonding for woodworking, furniture assembly, and more.

The HALOONG PUR Glue Machine is your go-to solution for precision, durability, and efficiency in industrial adhesive applications.

- Unmatched Bond Strength

- Eco-Friendly & Efficiency, Precise Dispensing

- Dual-Outlet Hose, Differentiate glue colors

Complete The Form To Request A Quote Today!

FAQ

Q: What is a PUR glue machine, and how does it differ from EVA systems?

A: A PUR glue machine uses polyurethane reactive (PUR) hot melt adhesive, which cures with moisture for superior strength and durability. Unlike EVA systems, which use traditional hot melt glue that weakens under heat or humidity, PUR offers a permanent bond, making it ideal for demanding applications like woodworking and furniture production.

Q: How does the HALOONG PUR Glue Machine compare to laser edge banding?

A: While laser edge banding provides a seamless finish, it’s costly and limited to specific materials. Our PUR glue machine offers greater versatility, bonding wood, and composites with adjustable settings, all at a lower operational cost.

Q: What materials can this PUR adhesive machine bond?

A: It’s designed for a wide range of materials, including MDF, plywood, solid wood, laminates, veneers, fabrics, films, and composites—perfect for woodworking, furniture, textiles, and construction industries.

Q: How do I maintain this industrial bonding equipment?

A: Maintenance is simple thanks to the dual Teflon-coated tank, which prevents glue buildup, and a self-cleaning system. Regular checks on the hose and temperature settings keep it running smoothly.

Q: Where can I buy a PUR glue machine like this?

A: Contact us directly via our website for a quote, demo. Trust HALOONG for top-tier quality.

Q: What’s the curing time for PUR adhesive compared to EVA?

A: PUR adhesive cures fully within 24-48 hours via moisture, forming a stronger bond than EVA, which sets instantly but lacks long-term resilience.

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.