Four-Spindle Dual-Station CNC Wood Router for Panel Furniture Manufactured

Category:

Model:

Specs & Details:

- Equipped with four independent spindles

- Spindle Power: 7.5kW (optimized for hardwoods)

- Tool Change Speed: 2 seconds

- Positioning: Pop-up pins for fast setup

- Dual station worktable

Price Range :

$8,999.00 – $10,999.00Price range: $8,999.00 through $10,999.00

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

Boost your panel furniture production efficiency with the HALOONG Four-Spindle Dual-Station CNC Wood Router. Building upon the success of our single-station four-spindle CNC cutting machines, this dual-station model offers a significant leap in productivity. It’s not just about doubling the output; it’s about maximizing throughput and minimizing downtime through a smart, continuous operation system.

Uninterrupted Workflow with Dual-Station CNC Wood Router

The ingenious dual-station workbench allows for alternating operation. While one station is processing, the operator can safely label, unload, and reload workpieces on the other. Once the first station completes its cycle, machining instantly begins on the pre-loaded second station. This continuous pendulum processing eliminates idle time, making it a cornerstone for high-volume furniture production.

Key Features and Benefits:

Highly Efficient Dual-Station Workbench:

Featuring two independent work zones for alternating operation, enabling near-continuous production cycles. Ideal for large-scale furniture manufacturing.

Powerful Four-Spindle System:

Equipped with four high-performance spindles, including an upgraded 7.5kW spindle specifically for heavy-duty cutting, ensuring efficient processing of various woodworking materials, including hardwoods. This is a powerful wood carving machine and CNC cutting machine in one.

Precision Multi-Axis Machining:

Offers precise multi-axis control for intricate 2D and 3D carving, profiling, and other complex operations crucial for high-quality furniture aesthetics.

Seamless Continuous Operation:

The dual-station design eliminates waiting times, ensuring a continuous production flow and significantly improving overall furniture manufacturing efficiency.

Enhanced Productivity and Flexibility:

Independent operation on both workstations provides exceptional flexibility, allowing manufacturers to optimize their workflow based on specific job requirements.

Versatile Material Processing:

Designed to handle a wide range of materials commonly used in panel furniture, including MDF, plywood, particleboard, solid wood, and laminates.

Reliable Control System:

Utilizes a user-friendly and robust control system (Lnc or Syntec), known for its precision and reliability in CNC machining operations.

Superior Workpiece Holding:

Each station features a uniquely designed grooved vacuum phenolic worktable with optimized airflow channels, ensuring superior holding power for various workpiece sizes and shapes. Includes pop-up pins for quick and accurate material positioning. This robust vacuum table design enhances efficiency.

High-Quality Components for Durability:

Built with high-precision linear guides, a robust transmission system (helical rack and pinion for X & Y axes, high-precision ball screw for Z axis), and reliable Japan SHIMPO or Newgear reducers for smooth, accurate, and long-lasting performance.

Fast and Accurate Automatic Tool Change:

Equipped with an automatic tool sensor for precise tool length measurement and achieves rapid tool changes (approximately 2 seconds, optional) thanks to the four-spindle design controlled by G-code.

Industry-Standard Software Compatibility:

Seamlessly integrates with popular CAD/CAM software used in the woodworking and furniture industry, such as Type3, UcancCAM, ArtcCAM, AlphCAM, Vectric, Enroute, MasterCAM, Cabinet Vision, and more.

Technical Specifications:

| Parameter | Description |

| Worktable Sizes (Each Station) | 4’x8′, 4’x9′, 5’x10′ (customizable) |

| Spindle Speed | Adjustable, up to 24,000 rpm |

| Number of Spindles | 4 |

| Spindle Power | Maximum single spindle power up to 7.5kW |

| Tool Change Speed | Approximately 2 seconds (Optional) |

| Drive System | Rack and pinion for X & Y axes, ball-screw for Z axis |

| Reducer | Japan SHIMPO or Newgear reducer for precise transmission |

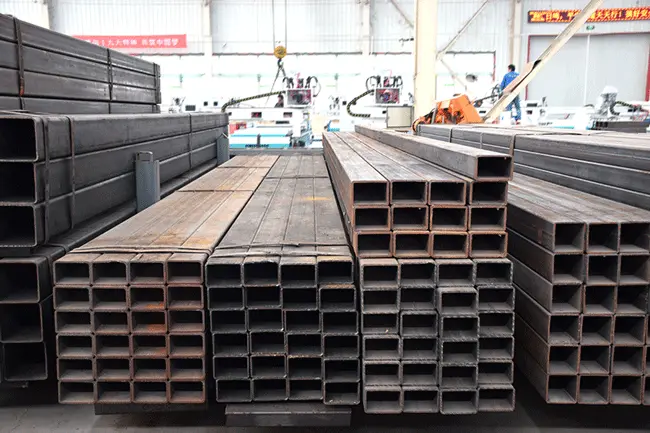

| Machine Structure | Reinforced steel frame for stability and durability |

| Work Table | Vacuum table with uniquely designed grooved airflow channels and pop-up pins on each station |

| Linear Guide | Square linear guides for smooth movement |

| Transmission | Helical rack and pinion for X & Y axes, high precision ball screw for Z axis |

| Lubrication System | Automatic lubrication system for reduced maintenance |

| Tool Calibration | Auto tool sensor for precise tool measurement |

| Cables | High-quality cables for reliable signal transmission |

| Compatible Software | Supports Type3, UcancCAM, ArtcCAM, AlphCAM, Vectric, Enroute, MasterCAM, Cabinet Vision, etc. |

| Command Language | G-code & M-code |

| Traveling Speed | Up to 60 m/min |

| Working Speed | Up to 20 m/min |

| Re-positioning Accuracy | ±0.04 mm/300 mm |

| System Resolution | High-resolution encoders for precise positioning |

| Working Accuracy | ±0.03 mm/300 mm |

| Working Air Pressure | Adjustable vacuum pressure for secure material holding |

| Working Voltage | 380V, 50Hz, 3-phase |

| Overall Dimensions | To be specified based on model |

| Machine Weight | To be specified based on model |

Why Choose the HALOONG Four-Spindle Dual-Station CNC Router?

- Double the Efficiency for Panel Furniture: Maximize your production capacity with continuous operation.

- Powerful Performance for Diverse Materials: Effortlessly process hardwoods and other materials with four high-performance spindles.

- Versatility for Various Furniture Tasks: From cutting and drilling to intricate carving and profiling, this machine handles it all.

- Unmatched Precision and Accuracy: Achieve flawless results and consistent quality with high-quality components and advanced controls.

- Robust Reliability and Durability: Built to withstand demanding industrial environments for long-term, high-output performance.

- Comprehensive Support from HALOONG: Benefit from our technical support, lifetime service commitment, and remote assistance.

Advantages in Furniture Production:

- Continuous Production Flow for Large Orders: Significantly reduce cycle times for substantial furniture orders with uninterrupted machining.

- Optimized for Sequential Operations in Furniture Making: Ideal for multi-step processes, allowing for specialized tasks on each station.

- Increased Throughput for Complex Furniture Sets: Rapidly produce complete furniture sets, including intricate components, even when working with hardwoods, thanks to the powerful spindles and dual stations.

Main Applications:

- High-volume production of wooden doors, cabinet bodies and doors, wardrobes, and other panel furniture.

- Manufacturing components for solid wood furniture like chairs, tables, and beds, especially those requiring powerful cutting of thicker hardwoods.

- Creating panels and parts for flat-pack furniture with high precision and speed.

- Carving decorative elements for furniture, such as intricate headboards.

- Producing custom furniture designs with varied machining requirements.

Comprehensive Support from HALOONG:

We are dedicated to providing exceptional support, including:

- Technical support via phone, email, and online resources.

- Lifetime service commitment to protect your investment.

- Remote assistance for quick troubleshooting and diagnostics.

- Optional on-site installation and training services for a smooth start.

Ready to Transform Your Furniture Production?

The HALOONG Four-Spindle Dual-Station CNC Wood Router is the ultimate solution for speed, precision, and efficiency in panel furniture manufacturing. Contact us today for a personalized consultation, request a quote, or schedule a demonstration to see how HALOONG can revolutionize your production line!

Maximize your panel furniture manufacturing throughput with the HALOONG Four-Spindle Dual-Station CNC Router. Expanding on the reliability of our single-station four-spindle CNC wood cutting machines, this dual-station system provides a substantial increase in production efficiency. It’s designed for continuous operation, minimizing downtime and maximizing output through its smart workflow.

The clever dual-station workbench facilitates seamless alternating work cycles. While one station is engaged in machining, the operator can efficiently prepare the next batch of materials on the adjacent station. Upon completion of the first cycle, the machine instantly transitions to the pre-loaded second station. This continuous processing approach ensures no wasted time, making it a key asset for high-volume furniture production.

- Equipped with four independent spindles

- Spindle Power: 7.5kW (optimized for hardwoods)

- Tool Change Speed: 2 seconds

- Positioning: Pop-up pins for fast setup

- Dual station worktable

Complete The Form To Request A Quote Today!

FAQ

General Questions:

- Q: What is a dual-station CNC wood router?

A: A dual-station CNC wood router features two independent worktables that can operate alternately. While machining occurs on one station, the operator can load or unload workpieces on the other, leading to continuous production. - Q: What are the benefits of a four-spindle CNC router?

A: A four-spindle CNC router is equipped with four spindles, allowing for multiple tools to be readily available for different operations (like cutting, drilling, and carving) without manual tool changes, significantly improving efficiency. - Q: What industries is this CNC router suitable for?

A: This CNC router is primarily designed for the panel furniture manufacturing industry, but it is also suitable for manufacturers of solid wood furniture, flat-pack furniture, custom furniture, and those creating decorative wood elements. - Q: What is the HALOONG brand known for?

A: HALOONG is committed to providing high-quality, reliable CNC machinery with a focus on enhancing production efficiency and offering comprehensive customer support.

Performance and Technical Questions:

- Q: What materials can this CNC router process?

A: This router can process a variety of materials commonly used in furniture manufacturing, including MDF, plywood, particleboard, solid wood, and laminates. - Q: What is the maximum spindle speed?

A: The spindle speed is adjustable, up to 24,000 rpm. - Q: What is the power of the spindles?

A: The maximum power of a single spindle can reach up to 7.5kW, specifically upgraded for heavy-duty cutting. - Q: How fast is the tool change?

A: The optional automatic tool change speed is approximately 2 seconds, thanks to the four-spindle design. - Q: What is the drive system used in this machine?

A: The machine uses a rack and pinion system for the X and Y axes and a ball-screw system for the Z axis. - Q: What kind of control system does it use?

A: It utilizes a user-friendly and robust control system, with options for Lnc or Syntec. - Q: What is the size of each worktable?

A: The standard worktable sizes for each station are 4’x8′, 4’x9′, 5’x10′ (customizable), with customizable options available. - Q: What is the accuracy of this CNC router?

A: The re-positioning accuracy is ±0.04 mm/300 mm, and the working accuracy is ±0.03 mm/300 mm. - Q: What is the working voltage required for this machine?

A: The machine requires a working voltage of 380V, 50Hz, 3-phase. - Q: Does it have automatic tool calibration?

A: Yes, it is equipped with an automatic tool sensor for precise tool length measurement. - Q: What kind of lubrication system does it have?

A: It features an automatic lubrication system to reduce maintenance. - Q: How does the vacuum table work?

A: Each station has a grooved vacuum phenolic worktable with optimized airflow channels to securely hold workpieces of various sizes and shapes. It also includes pop-up pins for precise material positioning.

Software and Compatibility Questions:

- Q: What CAD/CAM software is compatible with this CNC router?

A: This router supports various industry-standard CAD/CAM software, including Type3, UcancCAM, ArtcCAM, AlphCAM, Vectric, Enroute, MasterCAM, Cabinet Vision, etc. - Q: What is the command language used by the machine?

A: The machine uses G-code and M-code command languages.

Operational and Maintenance Questions:

- Q: How does the dual-station system improve efficiency?

A: The dual-station system allows for continuous operation by enabling the operator to load/unload one station while the other is processing, minimizing downtime and maximizing throughput. - Q: Is the machine easy to operate?

A: Yes, it features a user-friendly control system (Lnc or Syntec) designed for efficient machine operation. - Q: What kind of maintenance is required for this machine?

A: The machine is equipped with an automatic lubrication system to reduce maintenance. Regular cleaning and inspection are also recommended.

Support and Purchase Questions:

- Q: Does HALOONG provide technical support?

A: Yes, HALOONG offers technical support via phone, email, and online resources. - Q: What kind of service does HALOONG offer?

A: HALOONG is committed to providing lifetime service support for your investment. - Q: Is remote assistance available?

A: Yes, remote assistance is available for quick troubleshooting and diagnostics. - Q: Does HALOONG offer installation and training services?

A: Yes, optional on-site installation and training services are available to help you get started quickly. - Q: How can I get a quote for this CNC router?

A: You can contact us today for a personalized consultation and to request a quote. - Q: Can I schedule a demonstration of the machine?

A: Yes, you can schedule a demonstration to see how the HALOONG Four-Spindle Dual-Station CNC Wood Router can transform your production line.

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.