CNC Wood Router With Four-Spindle: Precision & Power for Furniture

Category:

Model:

Specs & Details:

- Equipped with four independent spindles

- Spindle Power: 7.5kW (optimized for hardwoods)

- Tool Change Speed: 2 seconds

- Positioning: Pop-up pins for fast setup

- Vacuum adsorption table

Price Range :

$8,999.00 – $10,999.00Price range: $8,999.00 through $10,999.00

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

Our Four-Spindle CNC Wood Router Machine is a high-efficiency device designed for panel furniture production, capable of simultaneously performing cutting, grooving, drilling, and profiling operations. This advanced machine features an automatic tool changer system and precision cutting tools, suitable for various complex patterns and materials, including MDF, plywood, and solid wood.

Key Features:

Multi-Process Capability:

Can perform multiple operations such as cutting, grooving, drilling, and profiling in a single setup, enhancing productivity.

High Precision:

Utilizes high-precision cutting tools for accurate and smooth processing.

- Automatic Tool ChangerEquipped with an automatic tool changer system to reduce labor costs and increase efficiency.

Easy Operation:

Features a user-friendly control interface, allowing operators to work efficiently without extensive technical background.

Comprehensive Support

Ideal For

- Panel furniture manufacturers

- Custom woodworking shops

- Businesses seeking a reliable CNC wood router

Upgrade Your Workshop Today

Technical Specifications of Four-Spindle CNC Wood Router

- Spindles: 4

- Spindle Power: 7.5kW (optimized for hardwoods)

- Tool Change Speed: 2 seconds

- Worktable Sizes: 4’x8′ (1220×2440 mm), 5’x10′ (1525×3050 mm), 5’x12′ (1525×3660 mm), 6’x12′ (1830×3660 mm) (customizable)

- Positioning: Pop-up pins for fast setup

- Connectivity: Network and USB ports

- Controls: Easy-to-use knobs, reset, and emergency stop

| Parameter | Description |

| Worktable Sizes: | 4’x8′ (1220×2440 mm), 4′ x 9′ (1220 x 2800mm), Customizable in other sizes |

| Maximum Power | 7.5kW |

| Spindle Speed | Adjustable, up to 24,000 rpm |

| Drive System | Rack and pinion for X & Y axes, ball-screw for Z axis |

| Reducer | Japan SHIMPO or Newgear reducer for precise transmission |

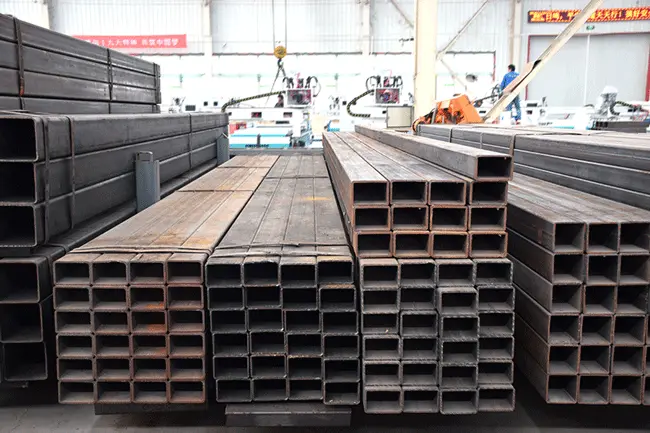

| Machine Structure | Reinforced steel frame for stability and durability |

| Work Table | Vacuum table for secure material holding |

| Positioning Cylinder | Pop-up pins for fast setup |

| Linear Guide | Taiwan PMI or HIWIN/THK square linear guides for smooth movement |

| Transmission | Helical rack and pinion for X & Y axes, high precision ball screw for Z axis |

| Lubrication System | Automatic lubrication system for reduced maintenance |

| Tool Calibration | Auto tool sensor for precise tool measurement |

| Cables | High-quality cables for reliable signal transmission |

| Compatible Software | Supports Type3, UcancCAM, ArtcCAM, AlphCAM, Vectric, Enroute, MasterCAM, Cabinet Vision, etc. |

| Command Language | G-code & M-code |

| Traveling Speed | Up to 60 m/min |

| Working Speed | Up to 20 m/min |

| Re-positioning Accuracy | ±0.04 mm/300 mm |

| System Resolution | High-resolution encoders for precise positioning |

| Working Accuracy | ±0.03 mm/300 mm |

| Working Air Pressure | Adjustable vacuum pressure for secure material holding |

| Working Voltage | 380V, 50Hz, 3-phase |

Why Choose This CNC Wood Router?

- Speed: Rapid tool changes and multi-spindle efficiency.

- Power: 7.5kW motor for hardwood precision.

- Versatility: Drills, mills, and carves with ease.

- Simplicity: User-friendly controls for all operators.

- Strength: Built for long-term, high-output performance.

Get Started Today

Main Applications :

- Furniture Production: Ideal for manufacturing wooden doors, cabinets, wardrobes, and other furniture components.

- Wooden Products: Suitable for processing speakers, game cabinets, computer desks, and musical instruments.

- Plate Processing: Applicable for insulating parts, PCBs, and various plastic materials.

- Cabinet Doors: Ideal for manufacturing wooden cabinet doors with intricate designs and precise cuts.

- Shaped Doors: Suitable for creating shaped doors with complex profiles.

Advantages :

- Efficiency: Reduces labor costs and production time with automatic tool changes and vacuum adsorption table.

- Precision: Ensures high accuracy and smooth operation with advanced drive systems and automatic tool setting.

- Flexibility: Supports a wide range of materials and applications.

Key Features and Benefits of Four-Spindle CNC Wood Router

Multi-Spindle Productivity

This CNC wood router comes with four independent spindles, allowing simultaneous use of multiple tools—such as milling cutters and drill bits—with tool switches in just 2 seconds. Perfect for high-volume production, it cuts downtime and maximizes output.Hardwood Mastery

Powered by a 7.5kW spindle motor, this CNC wood router tackles tough hardwoods effortlessly. It drills precise holes for furniture connectors like Cam Fittings and Pre-inserted Plastic Nuts, mills slots for back panels, and carves intricate cabinet designs with consistent quality.Easy-to-Use Design

Built for all skill levels, this CNC wood router features an intuitive control panel with knobs, a reset button, and an emergency stop. Network and USB connectivity simplify file transfers, while pop-up locating pins ensure fast, accurate material setup.Customizable Worktable

The vacuum adsorption worktable keeps panels secure, minimizing errors. Available in sizes like 4’x8′ (1220×2440 mm), 5’x10′ (1525×3050 mm), 5’x12′ (1525×3660 mm), or 6’x12′ (1830×3660 mm), this CNC wood router adapts to your needs with custom options.Precision and Durability

Constructed with a heavy-duty square steel frame, a high-precision gearbox, and a servo system, this CNC wood router ensures lasting reliability and exceptional accuracy—ideal for continuous, demanding workloads.Clean and Safe Operation

An integrated cutting, blowing, and dust collection system reduces debris, maintaining a tidy and healthy workspace, a must-have for modern CNC wood router users.

- Equipped with four independent spindles

- Spindle Power: 7.5kW (optimized for hardwoods)

- Tool Change Speed: 2 seconds

- Positioning: Pop-up pins for fast setup

- Vacuum adsorption table

Complete The Form To Request A Quote Today!

FAQ

General Questions

Q: What is the Four-Spindle CNC Wood Router designed for?

A: This CNC wood router is specifically engineered for panel furniture manufacturers, offering efficient cutting, drilling, and milling for high-volume production.

Q: What materials can this CNC wood router process?

A: It’s optimized for woodworking, including softwoods and hardwoods, with a 7.5kW spindle that excels at handling tough materials.

Q: What makes this CNC wood router stand out from others?

A: Its four-spindle design, 2-second tool change speed, 7.5kW power, and integrated dust collection system set it apart for efficiency and versatility.

Technical Specifications

Q: How many spindles does this CNC wood router have?

A: It features four independent spindles, allowing operations in G-code sequence.

Q: What is the spindle power?

A: The maximum spindle power is 7.5kW, ideal for cutting hardwoods with precision and speed.

Q: What are the available worktable sizes?

A: Standard options include 4’x8′ (1220×2440 mm), 4′ x 9′ (1220 x 2800mm), with custom sizes available.

Q: How fast is the tool change process?

A: Tool changes take just 2 seconds, minimizing downtime and boosting productivity.

Q: How precise is this CNC wood router?

A: It uses a high-precision gearbox and servo system to ensure accurate cutting, drilling, and milling.

Operation and Usability

Q: Is this CNC wood router easy to operate?

A: Yes, it features an intuitive control panel with knobs, a reset button, and an emergency stop, making it accessible for operators of all skill levels.

Q: What training is required to use this machine?

A: Basic CNC operation training is recommended, and we provide resources and support to get you started.

Q: What kind of user interface does it have?

A: The machine offers a user-friendly display and simple controls for efficient operation.

Q: How does the vacuum worktable function?

A: The vacuum adsorption system uses suction to securely hold panels in place, reducing movement and errors during processing.

Applications

Q: What specific tasks can this CNC wood router perform in furniture making?

A: It drills holes for furniture connectors (e.g., Cam Fittings, Pre-inserted Plastic Nuts), mills slots for back panels or LED strips, and carves intricate cabinet door designs.

Q: Can it handle custom furniture designs?

A: Yes, as a programmable CNC wood router, it supports precise custom patterns and designs.

Q: Is it suitable for high-volume production?

A: Absolutely, its four-spindle design and durable construction make it perfect for continuous, high-output workloads.

Maintenance and Support

Q: What maintenance does this CNC wood router require?

A: Regular cleaning, lubrication, and tool wear checks are recommended. Detailed guidelines are provided.

Q: What support is offered by the manufacturer?

A: We provide free technical support, lifetime service, and remote assistance to ensure smooth operation.

Cost and Investment

Q: How much does this CNC wood router cost?

A: Pricing depends on configuration and customization. Contact us for a tailored quote.

Q: What are the ongoing costs?

A: Expect expenses for maintenance, tool replacements, and potential software updates.

Q: What’s the expected return on investment (ROI)?

A: With increased output and reduced labor time, this CNC wood router offers a strong ROI for busy workshops.

Comparison and Features

Q: How does it compare to single- or dual-spindle CNC routers?

A: The four-spindle design delivers higher efficiency and faster processing than single- or dual-spindle models, especially for complex tasks.

Q: What are its unique features?

A: Key highlights include 2-second tool changes, a 7.5kW spindle for hardwoods, and an integrated cutting-blowing-dust collection system.

Q: Does it integrate with existing production systems?

A: Yes, it supports network and USB connectivity for seamless data transfer and workflow integration.

Additional Technical Details

Q: What is the power consumption?

A: The 7.5kW spindle is the primary power draw; total consumption varies by usage and should be confirmed with specs.

Q: How noisy is the machine during operation?

A: Noise levels are comparable to similar CNC routers, with the dust collection system helping to reduce overall sound.

Q: What is the expected lifespan of this CNC wood router?

A: With proper maintenance, it’s built for years of reliable service, backed by lifetime support.

Q: What software does it use?

A: It’s compatible with standard CNC software (e.g., supporting G-code); exact software details should be confirmed.

Q: What file formats are supported?

A: Common formats like DXF and G-code are supported for design and operation.

Q: Is the vacuum pump included?

A: Check with us—some configurations include it, while others may require a separate purchase.

Q: What safety features are included?

A: It comes with an emergency stop button and standard safety guards to protect operators.

Q: What are the machine’s dimensions and weight?

A: Exact size and weight depend on configuration; contact us for precise details.

Q: What are the installation requirements?

A: A level surface, proper ventilation, and adequate power supply are needed—full details available upon request.

Conclusion

This Four-Spindle CNC Wood Router combines power, precision, and ease of use, making it an excellent investment for panel furniture production. Have more questions? Reach out to our team for personalized answers!

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.