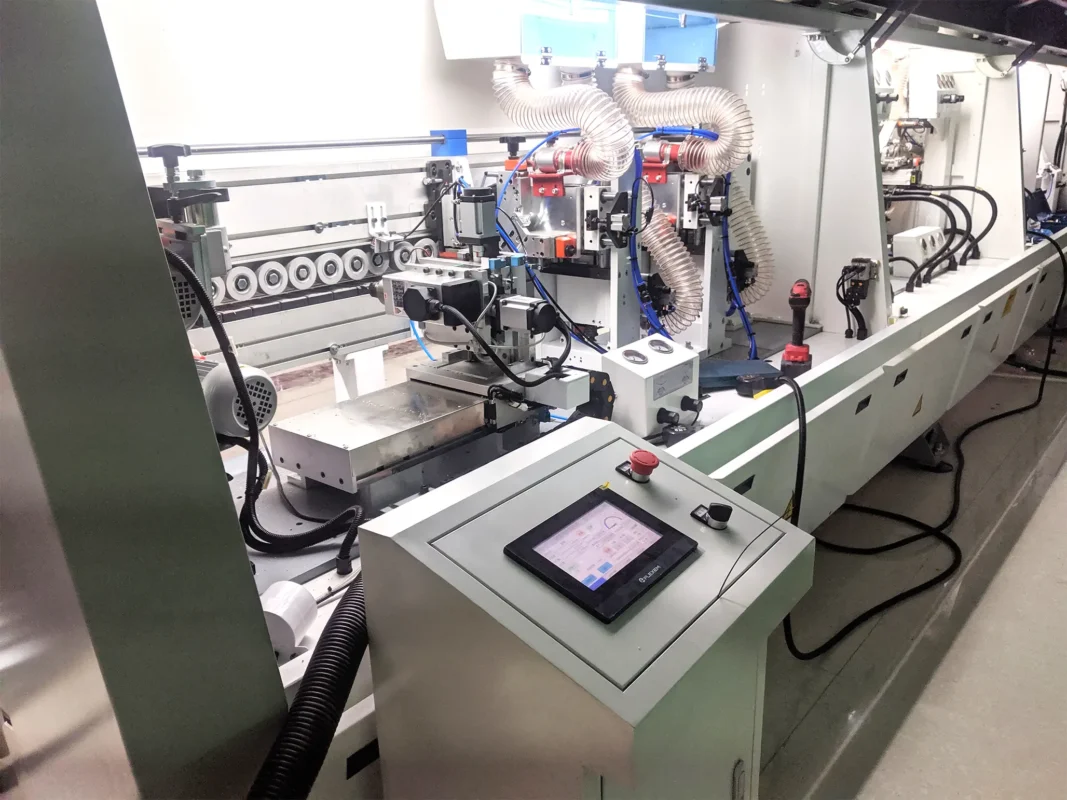

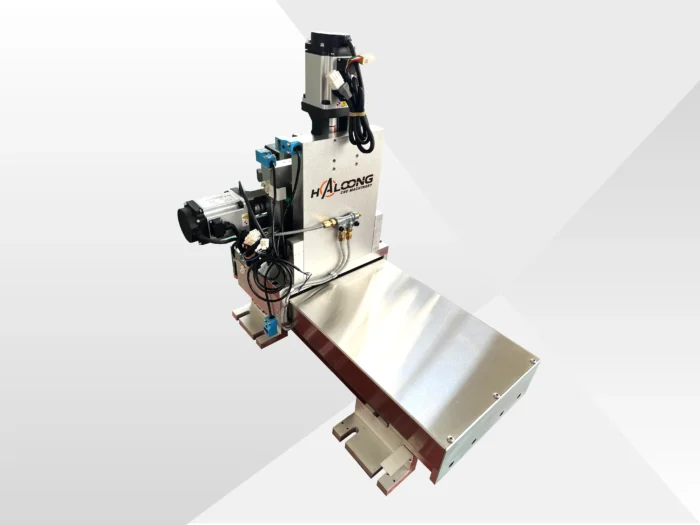

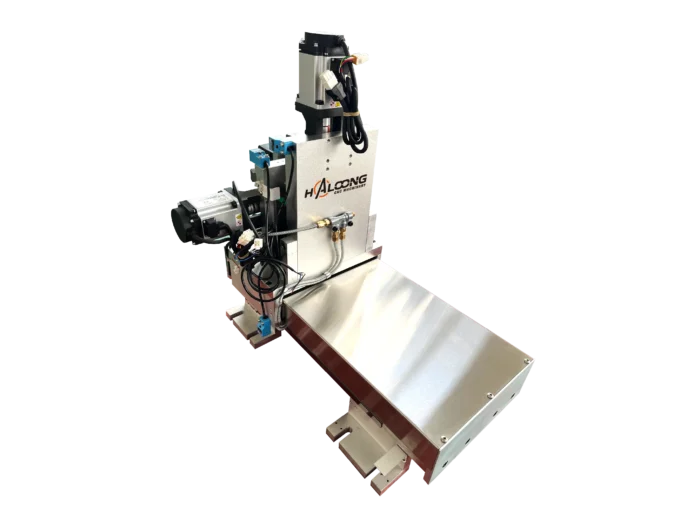

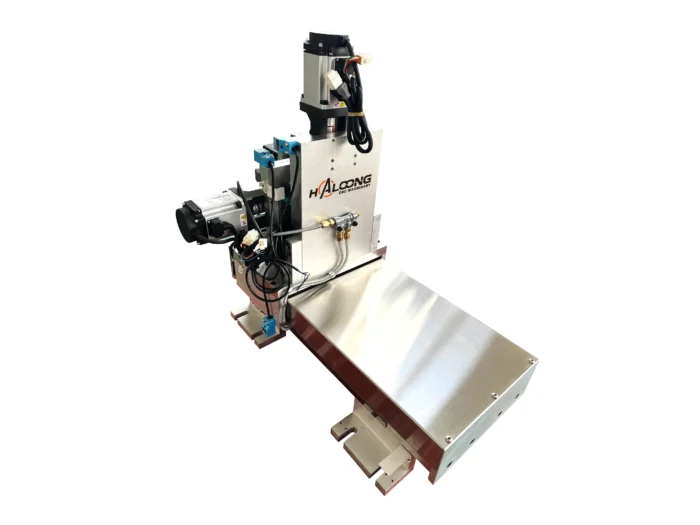

Magnetic Levitation Edge Banding Machine Synchronous Side Drilling Kit

Category:

Model:

Specs & Details:

- Edge banding ,side drilling 2-in-1

- Easy retrofitting

- Magnetic Levitation Precision

Price Range :

$2,599.00 – $2,999.00Price range: $2,599.00 through $2,999.00

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

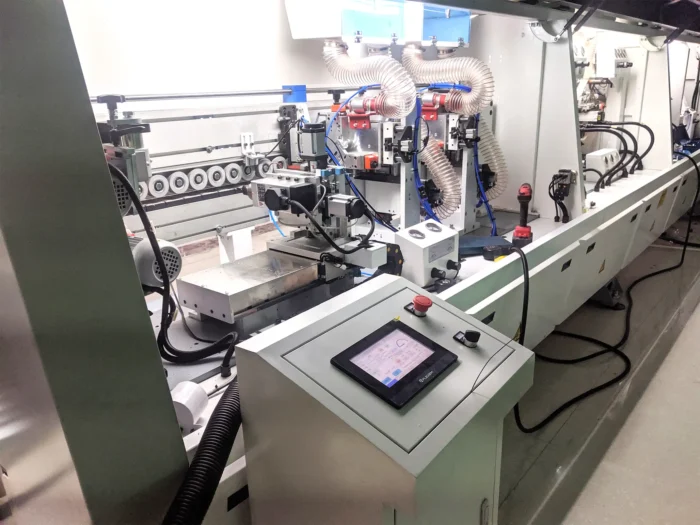

Enhance Your Edge Banding with the Magnetic Levitation Synchronous Side Drilling Kit

Why Choose the Drilling Retrofit Kit?

Magnetic Levitation Precision:

- Unlike traditional mechanical systems, magnetic levitation reduces friction and vibration, delivering pinpoint accuracy for side holes.

Time-Saving Dual Action:

- Performs edge banding and drills three-in-one connector holes simultaneously, outpacing standalone drilling methods.

Enhanced Durability:

- Contactless levitation technology minimizes wear on components, extending the life of your equipment.

Easy Integration:

- Retrofit design fits most standard edge banding machines, with intuitive controls for seamless use.

Technical Specifications

Feature | Details |

|---|---|

synchronous drilling speed | 10-30m/min |

Hole Diameter Range | Based on the diameter of your drill bit |

Power Consumption | 3.5 kW (4.7 HP) |

Width | 550 mm (22in) |

Weight | 30 kg (66 lbs) |

Key Applications of edge-banding drilling-kit

Woodworking:

- Drills precise side holes in MDF, plywood, and solid wood during edge banding.

Furniture Manufacturing:

- Streamlines cabinet and shelf production with three-in-one connector compatibility.

Construction:

- Enhances efficiency in pre-drilled panel and frame assembly.

Advantages Over Traditional Methods

- Edge banding ,side drilling 2-in-1

- Easy retrofitting

- Magnetic Levitation Precision

Complete The Form To Request A Quote Today!

FAQ

<div class=”css-146c3p1 r-bcqeeo r-1ttztb7 r-qvutc0 r-37j5jr r-a023e6 r-16dba41 r-1adg3ll r-1b5gpbm r-a8ghvy”>r=”ltr”><span class=”css-1jxf684 r-bcqeeo r-1ttztb7 r-qvutc0 r-poiln3″>It adds synchronous side hole drilling, eliminating the need for separate side drilling tools or steps, saving time and ensuring hole-edge alignment.</span></span>

<div class=”css-146c3p1 r-bcqeeo r-1ttztb7 r-qvutc0 r-37j5jr r-a023e6 r-rjixqe r-b88u0q” dir=”ltr”>3. What are three-in-one connectors, and why are they important?</span>

<div class=”<span class=”>Three-in-one connectors are hardware used in woodworking to join panels, requiring precise side holes. This kit drills them perfectly in sync with edge banding.

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

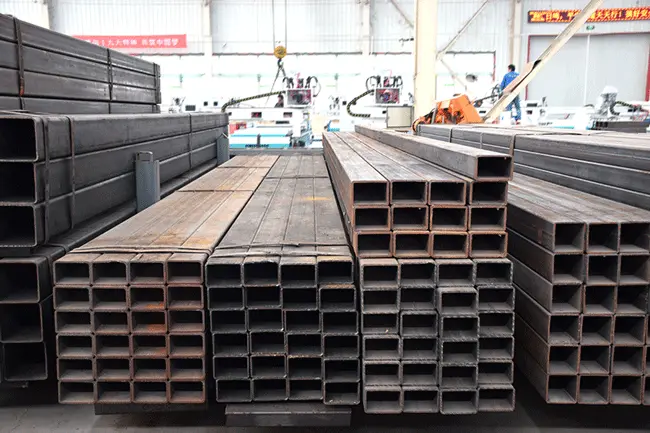

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.