Dual Station Table Linear ATC CNC Wood Router: Automatic Tool Changer Wood CNC for Furniture Making

Category:

Model:

Specs & Details:

- 12-tool linear magazine

- Tool changes in under 5 seconds

- Automated Tool Calibration

- Process a Wide Range of Materials

- Invisible Connectors (e.g., Lamello, Peanut,Lockdowel).

- Dual Table Start the factory’s maximum order-taking mode

Price Range :

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

Boost Your Output with the HALOONG Dual Table 12-Tool Automatic Tool Changer CNC Wood Router!

Are you struggling with high order volumes and inefficient production? The HALOONG Dual Table 12-Tool Automatic Tool Changer CNC Wood Router is here to revolutionize your woodworking operations! Featuring a dual-workzone design for simultaneous or alternating processing, coupled with a powerful automatic tool changer, this woodworking CNC machine allows your factory to produce high-quality furniture continuously and efficiently. Meet growing market demands and significantly increase your profitability with this state-of-the-art CNC router for furniture production.

Key Features

High-Efficiency Dual Table System:

- Continuous Production: The dual-worktable design supports alternating processing. While one table is being machined, the other can be loaded or unloaded, enabling truly continuous production without downtime, significantly boosting efficiency.

Lightning-Fast Tool Changes:

The 12-tool automatic tool changer (ATC) system boasts tool change times of under 5 seconds, ensuring uninterrupted and highly efficient processing.

Powerful Machining Capability:

Equipped with a robust 9kW automatic tool changer spindle, this CNC wood router easily handles the high-volume processing of various wood types and composite materials.

Precise and Efficient Positioning:

Pop-up locating pins on each worktable ensure quick and accurate material setup every time.

Wide Material Compatibility:

Capable of processing MDF, solid wood, PVC, acrylic, aluminum composite panels, engineered wood, and more, catering to diverse production needs.

Intelligent Control System:

Features an advanced CNC controller (e.g., Syntec, Lnc) optimized for dual-table operation, offering user-friendly operation and stable performance.

Precise Transmission System:

High-precision helical rack and pinion drives on the X and Y axes, combined with a ball screw on the Z-axis, guarantee accuracy and stability during high-load continuous machining.

Comprehensive Accessory Package:

Includes an automatic tool setter, an integrated dust extraction system, and a standard push-off system.

Healthier Workshop Environment:

The efficient built-in dust collection system effectively captures dust even during continuous dual-table operation, maintaining a clean and safe workspace.

Product Parameters

| Parameter | Specification |

| Machine Type | HALOONG Dual Table 12-Tool Automatic Tool Changer (ATC) CNC Wood Router |

| Positioning | Pop-up locating pins on each worktable for quick, accurate material setup |

| Table Type | Dual Worktable Vacuum Table or T-Slots(single table is here) |

| Tool Magazine Type | Linear, Gantry-Mounted |

| Maximum Tool Change Time | < 5 Seconds |

| Spindle Power | 9kW Automatic Tool Changer Spindle |

| Spindle Type | Air-Cooled |

| Spindle Speed | Typically 18,000 – 24,000 RPM (Specify based on model) |

| Single Worktable Area Options | 4′ x 8′ (1300 x 2500mm) / 4′ x 9′ (1300 x 2800mm) Customizable in other sizes (Total machining area is double the single worktable size) |

| X, Y, Z Axis Motors | High-Performance Servo Motors |

| X, Y, Z Axis Transmission | High-Precision Helical Rack and Pinion (X, Y), Ball Screw (Z) |

| Guide Rails | High-Precision Linear Guide Rails |

| Control System | Advanced CNC Controller (e.g., Syntec, Lnc) with dual-table control support |

| Positioning Accuracy | ±0.03mm |

| Repeatability | ±0.02mm |

| Maximum Rapid Travel Speed | (Specify based on model, e.g., 60-80 m/min) |

| Maximum Cutting Speed | (Specify based on model, e.g., 25-40 m/min) |

| Supported Materials | MDF, Solid Wood, PVC, Acrylic, Aluminum Composite Panels, Engineered Wood |

| Interface | Ethernet, USB |

| Pop-up Positioning Pins | Included on each worktable |

| Automatic Tool Setter | Included |

| Dust Extraction System | Integrated system with multiple collection ports, optimized for dual-table operation |

| Automatic Loading/Unloading | Standard Push-Off System, Optional Infrared Unloading Platform, supports dual-table operation |

| Frame Structure | Heavy-Duty Welded Steel Frame, enhanced stability for dual-table operation |

| Operating Voltage | Typically 3-Phase, 220V or 380V (Specify based on model) |

| Operating Temperature | 5°C – 45°C |

| Software Compatibility | Compatible with Standard CAM Software, supports dual-table programming |

| Machine Weight | (Specify based on model) |

| Machine Dimensions | (Specify based on model) |

| Technical Support | Free Technical Support, Lifetime Support, Remote Online Assistance |

| Lubrication System | Automatic lubrication system for reduced maintenance |

The Unique Advantages of the HALOONG Dual Table CNC Wood Router

Revolutionize Your Efficiency, Double Your Potential Output: The dual-table design is the cornerstone of this HALOONG CNC machine. It allows you to load or unload materials on one worktable while machining is in progress on the other, achieving truly continuous production. For furniture factories dealing with large production runs of identical or similar workpieces, this translates to a significant leap in efficiency, reduced lead times, and enhanced market competitiveness.

Save Time and Labor Costs: Say goodbye to the inefficient single-table machine model where operators wait for loading and unloading. The dual-table design drastically reduces operator idle time and lowers labor intensity, ultimately reducing your overall production costs.

Optimize Your Production Workflow: The dual-table configuration makes your production workflow smoother and more efficient. You can flexibly choose between alternating or simultaneous machining modes based on order requirements, optimizing your production schedule and better handling rush orders.

Applications of the HALOONG Dual Table CNC Wood Router

- High-Volume Furniture Production: Ideal for the continuous, large-scale production of standardized furniture components such as cabinet doors, wardrobe side panels, and headboards.

- Efficient Custom Furniture Manufacturing: Significantly boosts production efficiency when processing custom orders involving multiple identical or similar parts.

- Door Manufacturing: Suitable for the batch production of wooden doors, frame doors, and more.

- Panel Furniture Production: Enables the fast and efficient manufacturing of various types of panel furniture.

Leading the Way in Production Efficiency

Compared to other CNC wood routers in its class, the HALOONG Dual Table 12-Tool Automatic Tool Changer stands out with its unparalleled efficiency advantages:

- Double the Production Capacity Potential: The dual-table design directly leads to increased production capacity.

- Reduced Downtime: The continuous loading and unloading operation minimizes machine idle time.

- Enhanced Competitiveness: Higher production efficiency translates to lower production costs and faster delivery times, helping you gain a significant edge in the competitive market.

Inquire Now and Enter the Era of High-Efficiency Dual Station Table Production with HALOONG!

The HALOONG Dual Table 12-Tool ATC CNC Wood Router is the ultimate solution for boosting your furniture production efficiency and handling large order volumes. Whether you need to expand your production capacity or want to upgrade your existing operations, this machine is designed to meet your needs. Contact us today for more information on our dual-table models and customization options, and let HALOONG help your factory achieve a significant leap in productivity!

Why the HALOONG 12-Tool ATC CNC Wood Router Stands Out

The HALOONG 12-Tool ATC CNC Wood Router is a high-performance wood CNC machine built for exceptional efficiency and flexibility. Its automatic tool changer (ATC) switches between 12 tools in under 5 seconds, drastically reducing downtime and boosting output. Whether you’re cutting MDF, carving solid wood, or crafting intricate designs, this CNC wood router handles it all with ease. For even greater productivity, consider our optional dual-table configuration, which allows for near-continuous operation and significantly increases throughput for demanding production schedules.

Key Features of This CNC Wood Router

Here’s what makes this wood CNC a must-have:

Ultra-Fast Tool Switching

- 12-tool linear magazine: Holds a variety of tools, ready for instant use.

- Tool changes in under 5 seconds: The gantry-integrated design cuts travel time, keeping your production moving.

Versatile Material Processing

- Works with MDF, solid wood, OSB, PVC, acrylic, aluminum, and composite panels.

- Supports standard furniture joints (e.g., dowels and cams) and modern invisible connectors (e.g., Lamello, Peanut, Lockdowel).

- Perfect for cabinets, wardrobes, doors, and artistic carvings.

Customizable Worktable Options

- Options like 4’x8′ (1220×2440 mm), 4’x9′ (1220×2800 mm), or custom sizes available for single-table models.

- Maximize your output with our optional dual-table configuration, allowing for continuous loading and unloading on separate work zones.

- Upgraded vacuum table locks materials securely for flawless results on both single and dual-table setups.

Effortless Operation

- User-friendly controls with a clear display, network, and USB connectivity.

- Simplified design means even beginners can master it quickly. The dual-table operation is also intuitively managed through the advanced control system.

Built to Last with Precision

- Heavy-duty steel frame and high-precision gearbox for durability.

- Servo-driven system ensures smooth, accurate cuts every time. The robust construction ensures stability even during continuous operation on the dual-table model.

Cleaner, Safer Workspace

- Integrated dust collection and air-blow system keeps debris in check.

- Ideal for continuous, high-output runs without mess, making it perfect for the increased production demands of the dual-table system.

Top-Notch Support

- Free technical support, lifetime service, and remote assistance included.

- 12-tool linear magazine

- Tool changes in under 5 seconds

- Automated Tool Calibration

- Process a Wide Range of Materials

- Invisible Connectors (e.g., Lamello, Peanut,Lockdowel).

- Dual Table Start the factory’s maximum order-taking mode

Complete The Form To Request A Quote Today!

FAQ

Q: What is an automatic tool changer (ATC) CNC wood router, and why is it beneficial for furniture manufacturing?

A: An ATC CNC wood router is a computer-controlled cutting machine that can automatically switch between different cutting tools without manual intervention. This significantly increases production efficiency, reduces downtime, and allows for complex machining operations like cutting, drilling, and carving in a single setup, ideal for demanding furniture production. Our HALOONG model is also available with an optional dual table, further enhancing efficiency for high-volume production.

Q: How many tools can this CNC wood router accommodate?

A: This model is equipped with a 12-position linear tool magazine, allowing you to have up to 12 different cutting tools readily available for various machining tasks. This is particularly advantageous for complex projects and continuous operation, especially on our dual-table configurations.

Q: How fast is the tool changing process on this machine?

A: Our gantry-integrated tool magazine enables tool changes in under 5 seconds right at the machining head, minimizing non-productive time and maximizing your spindle’s cutting time. This rapid tool change is crucial for maximizing the throughput of both single and dual-table models.

Q: What types of furniture joinery can this CNC wood router handle with its 12 tools?

A: This versatile machine can handle traditional furniture joinery like the three-in-one connector system, as well as advanced concealed connection methods such as Lamello, Peanut, and Lockdowel, providing flexibility for diverse design requirements. The availability of 12 tools makes even intricate joinery on high-volume, dual-table production runs efficient.

Q: Is this CNC wood router suitable for intricate carving and cabinet door designs?

A: Absolutely! With 12 tool positions, this machine excels at complex carving tasks, allowing for detailed and diverse cabinet door designs and other decorative elements. The precision and tool capacity make it ideal for creating high-quality, detailed work, whether on a single or dual table.

Q: How user-friendly is the operation of this automatic tool changer CNC?

A: We’ve designed the operation to be intuitive and easy to learn, even for operators who are not highly experienced. The user-friendly interface and simplified workflows minimize the learning curve. The control system for our dual-table models is also designed for ease of use, allowing for efficient management of both work zones.

Q: What materials can be processed using this CNC wood router?

A: This machine is capable of processing a wide range of materials commonly used in the furniture industry, including MDF, solid wood, PVC, acrylic, aluminum composite panels, and other engineered wood products. The dual-table option doesn’t limit the material compatibility, allowing for versatile production.

Q: What worktable sizes are available for this CNC wood router? Can I customize the size?

A: We offer standard worktable sizes of 4′ x 8′, 4′ x 9′. (You can also customize other sizes according to your material.) For our dual-table models, these sizes refer to each individual work zone. We also provide options for custom worktable sizes to meet your specific production needs, including customized dual-table configurations.

Q: Does this CNC wood router come with a dust collection system?

A: Yes, it features a newly designed integrated cutting, blowing, and dust extraction system to ensure a cleaner and healthier working environment by effectively collecting machining debris. Our dual-table models also benefit from this efficient dust collection system, maintaining a clean workspace even during continuous operation.

Q: What kind of support and service do you provide with this machine?

A: We offer free technical support, lifetime machine support, and remote online assistance to ensure you have the resources you need for successful operation and maintenance, regardless of whether you choose a single or dual-table model.

Q: Does this CNC wood router have an automatic tool setter for precise tool calibration?

A: Yes, it is equipped with an automatic tool setter, which automates the process of measuring tool lengths, saving time and improving machining accuracy. This feature is essential for maintaining precision in both single and dual-table operations.

Q: What is the power of the automatic tool change spindle on this machine?

A: This model features a powerful 9kW automatic tool change spindle, providing ample power for various cutting and carving applications on both single and dual-table configurations.

Q: Does this CNC wood router have any features to automate material unloading?

A: Yes, it comes standard with an automatic push-off and dust removal system for efficient material unloading. Our dual-table models are specifically designed to maximize the benefits of these automation features, allowing for near-continuous production.

Q: Is this CNC wood router suitable for both industrial production and hobbyist use?

A: While designed with industrial applications in mind for continuous, multi-shift operation and high-volume production, its competitive pricing also makes it a viable option for serious woodworking enthusiasts looking for professional-grade capabilities and creative freedom. The dual-table option is particularly geared towards industrial and high-volume production environments.

Q: What kind of CNC technology does this router utilize for high-speed and high-power performance?

A: This ATC wood CNC router employs advanced CNC technology to deliver high-speed and high-power performance, ensuring efficient and accurate machining. It also features pop-up positioning pins for quick and accurate material placement on both the single and dual-table versions.

Q: What kind of interfaces does the machine offer for data transfer?

A: The machine provides both network and USB interfaces for convenient and reliable data transfer of your design files for both single and dual-table operations.

Q: What is the warranty on this CNC wood router?

A: We offer a 1 year warranty on this CNC wood router, covering both single and dual-table configurations.

Q: How can I get more information or a quote for this machine, including the dual-table option?

A: Please contact us through our website, by phone, or by email to request more information or a personalized quote. Be sure to mention your interest in the dual-table configuration if that suits your production needs. Our sales team will be happy to assist you.

Q: What are the benefits of choosing the dual-table configuration for this HALOONG CNC wood router?

A: The dual-table configuration significantly increases production efficiency by allowing for continuous operation. While one worktable is processing, you can load or unload material on the other, minimizing downtime and maximizing throughput, especially for large production runs.

Q: Is the dual-table operation easy to manage with the CNC control system?

A: Absolutely. The advanced CNC control system is designed with user-friendliness in mind and provides intuitive controls for managing both work zones.

Q: Is the footprint of the dual-table CNC wood router significantly larger than the single-table version?

A: While the dual-table model will have a larger overall footprint to accommodate the two worktables, we have optimized the design to be as space-efficient as possible while providing maximum productivity. Please contact us.

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

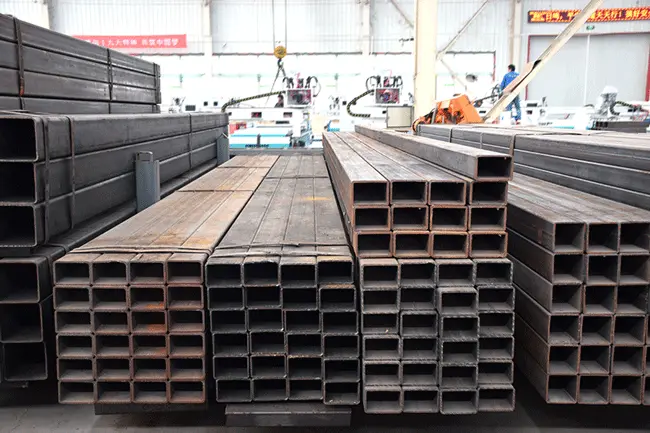

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.