CNC Dual Spindle Side Slotting and Drilling Machine

Category:

Model:

Specs & Details:

- integrated processing for Lamello and Lockdowel systems

- dual-spindle CNC side drilling machine

- Barcode scanning + infrared laser positioning

- Independent oil-water separation system

Price Range :

$2,899.00 – $2,999.00Price range: $2,899.00 through $2,999.00

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

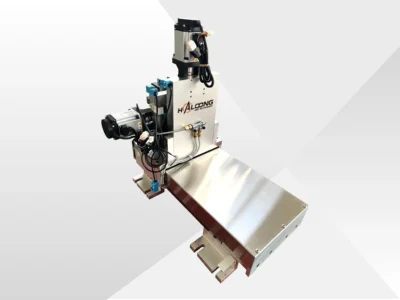

The Dual-Spindle CNC Side Drilling Machine represents the next generation of automated woodworking machinery, specifically designed for professionals in panel furniture production. This advanced side drilling machine excels in the precise and efficient drilling of horizontal side holes and integrated processing for various concealed connectors (including Lamello and Lockdowel systems). By featuring two spindles that operate simultaneously—one for drilling and the other for milling or concealed connector applications—this CNC wood machine eliminates the need for manual tool changes, offering a seamless, high-speed, and highly productive solution for modern furniture manufacturing.

Product Specifications

| Parameter | Details |

| Control System | Custom PLC system, high stability, anti-interference, intuitive touchscreen interface |

| Positioning System | Laser probe (USA-made), 20-300mm (0.79-11.81 in) range, compatible with various colors and materials |

| Spindle | Dual high-power spindles, ensuring precision round holes without oval distortion |

| Drive System | Dual servo motors: X-axis 750W, Y-axis 400W |

| Transmission | X-axis: Gear and rack with reducer, ±0.02mm (±0.0008 in) accuracy; Y-axis: Ball screw + linear guide |

| Worktable | High-strength PVC, 3 independent zones with separate control buttons |

| Dimensions | Approx. 3300mm x 1250mm x 1300mm (129.9 in x 49.2 in x 51.2 in) (may vary by model) |

| Weight | Approx. 1200-1500kg (2645-3307 lbs) (model-dependent) |

| Drilling Modes | Barcode scanning + infrared laser positioning, G-code compatible |

| Supported Materials | Solid wood, MDF, particleboard, fiberboard |

| Functions | Side holes, dowel holes, stepped holes, side grooving, integrated processing for various concealed connectors (including Lamello and Lockdowel systems) |

| Power Supply | 380V/50Hz (customizable for some regions) |

| Air Pressure | 0.6-0.8 MPa (87-116 PSI) |

| Lubrication | Smart auto-lubrication system for moving parts |

| Air Filtration | Independent oil-water separation system for clean air supply |

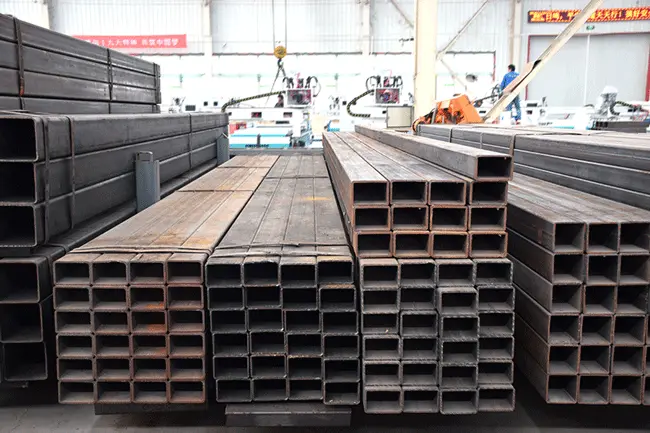

| Bed Structure | Heavy-duty square tube welded frame, stress-relieved, precision-milled by CNC gantry mill |

Detailed Description

The Dual-Spindle CNC Side Drilling Machine redefines woodworking efficiency and versatility. This innovative CNC wood machine integrates dual spindles to streamline production processes. Here’s why it’s a significant advancement:

Enhanced Productivity with Dual-Spindle Technology

- Featuring two powerful spindles that operate simultaneously, this dual-spindle CNC side drilling machine allows for concurrent drilling of side holes and milling or integrated processing for various concealed connectors (including Lamello and Lockdowel systems). This eliminates the downtime associated with manual tool changes and realignments, significantly increasing throughput.

- Barcode scanning enables seamless integrated processing for various concealed connectors (including Lamello and Lockdowel systems), allowing for complex tasks such as drilling dowel holes and creating side grooves for these connectors to be completed in a single, efficient cycle.

- The high-speed spindles ensure the creation of perfectly round holes without any oval distortion, maintaining exceptional precision in every operation.

Precision and Accuracy in Woodworking

- Equipped with a high-precision laser probe manufactured in the USA, this side drilling machine accurately detects workpiece surfaces within a range of 20-300mm (0.79-11.81 in), regardless of color or material. It achieves a remarkable positioning accuracy of ±0.02mm (±0.0008 in).

- The X-axis incorporates a servo motor with a robust gear-and-rack transmission and a reducer, while the Y-axis utilizes a ball screw and linear guide system. This combination ensures unwavering stability and precision even at high operating speeds.

Efficiency and Adaptability for Diverse Projects

- The machine offers dual operational modes—barcode scanning and laser positioning—and is compatible with G-code via a barcode scanner, ensuring rapid setup and processing for maximized productivity in your woodworking tasks.

- The worktable, made of high-strength PVC, can be divided into three independent zones for processing shorter panels or combined to accommodate boards up to 3300mm (129.9 in) in length, providing exceptional adaptability to various project requirements.

- Dual servo motors facilitate automatic drilling height adjustment in approximately 1 second, minimizing downtime when switching between workpieces of different thicknesses.

User-Friendly Operation for Woodworking Professionals

- The intuitive touchscreen interface features large, easily recognizable icons and supports both scanning and laser modes. Its user-friendly design requires minimal training, allowing operators to become proficient quickly, without the need for highly specialized technicians.

- The seamless collaboration between the two spindles ensures uninterrupted workflow during process changes, further enhancing operational efficiency in your panel furniture production.

Robust Durability and Multi-Functional Capabilities

- Constructed with a heavy-duty welded steel frame that has been stress-relieved and precision-milled by a CNC gantry mill, this CNC wood machine is built to withstand continuous high-speed operation, ensuring long-term durability and reliability.

- An automatic lubrication system extends the service life of critical components, while an independent oil-water separation air filter delivers clean air at an optimal pressure of 0.6-0.8 MPa (87-116 PSI) to protect the pneumatic system.

- This versatile machine efficiently processes a wide range of materials, including solid wood, MDF, and particleboard, and can perform various functions such as drilling side holes, dowel holes, and stepped holes, as well as side grooving and integrated processing for various concealed connectors (including Lamello and Lockdowel systems).

Applications

Panel Furniture Production:

Ideally suited for manufacturing cabinets, wardrobes, shelves, and furniture requiring integrated processing for various concealed connectors (including Lamello and Lockdowel systems) with high precision and efficiency.

Woodworking Shops:

Significantly accelerates the completion of bespoke furniture projects for small to medium-sized businesses, offering advanced capabilities like dual-spindle drilling and concealed connector processing.

Factory Lines:

Integrates seamlessly with other automated equipment such as CNC routers and edge banders to create a streamlined, high-output workflow for large-scale panel furniture production utilizing Lamello, Lockdowel, and other similar systems.

Why Buy This Dual-Spindle CNC Side Drill?

Significantly Boosted Productivity:

The dual-spindle design eliminates tool change delays, effectively doubling your output and leading to faster project turnarounds in your woodworking operations.

Substantial Cost Savings:

Automation reduces the need for manual labor and minimizes errors, resulting in significant reductions in operational expenses for your panel furniture business.

Premium Quality and Enhanced Aesthetics:

The precise drilling and integrated processing for concealed connectors enhance both the durability and the aesthetic appeal of your finished furniture products.

Simple and Intuitive Operation:

The user-friendly controls and the requirement for only minimal training make this advanced machine accessible to all members of your team.

Exceptional Versatility and High ROI:

From basic side drilling to intricate integrated processing for Lamello and Lockdowel systems, this dual-spindle CNC side drilling machine handles a wide range of tasks, providing a high return on your investment.

Upgraded high-efficiency side hole solution

Take your woodworking capabilities to the next level! Contact us today to discover more about the Dual-Spindle CNC Side Drilling Machine or to schedule a personalized demonstration. Invest in this industry-leading side drill tool now and unlock unparalleled precision, efficiency, and profitability in your furniture manufacturing!If you are considering drilling six sides in one process, then the more advanced CNC Six Sided Drilling Machine is here.

The Dual-Spindle CNC Side Drilling Machine is a next-generation CNC wood machine crafted for woodworking professionals, particularly in panel furniture production. This advanced side drill tool excels at drilling horizontal side holes and processing hidden fittings with precision and efficiency, overcoming the limitations of traditional three-axis CNC routers. With two spindles working in unison—one for drilling, the other for milling or hidden fitting tasks—this machine eliminates the need for manual tool changes, offering a seamless, high-speed solution for modern furniture manufacturing.

- integrated processing for Lamello and Lockdowel systems

- dual-spindle CNC side drilling machine

- Barcode scanning + infrared laser positioning

- Independent oil-water separation system

Complete The Form To Request A Quote Today!

FAQ

Q: What is the primary function of the Dual-Spindle CNC Side Drilling Machine?

A: This machine is primarily designed for precisely and efficiently drilling horizontal side holes in wood panels, which is essential for panel furniture construction. Additionally, the dual-spindle design allows for integrated processing of concealed furniture connectors like Lamello and Lockdowel, eliminating the need for manual tool changes.

Q: What are the benefits of having a dual-spindle system on this CNC wood machine?

A: The dual-spindle system significantly increases productivity by allowing simultaneous drilling and milling or concealed fitting processing. This eliminates downtime for manual tool changes, leading to faster production cycles and higher output.

Q: What types of concealed furniture connectors can this machine process?

A: This machine offers integrated processing for various concealed connectors, including popular systems like Lamello and Lockdowel. It can handle the necessary machining for these types of connections.

Q: What materials can the Dual-Spindle CNC Side Drilling Machine work with?

A: The machine is capable of processing a variety of wood-based materials, including solid wood, MDF, particleboard, and fiberboard.

Q: Is this CNC side drilling machine easy to operate? Do I need specialized technicians?

A: Yes, the machine features an intuitive touchscreen interface with large icons and dual-mode operation (scanning or laser). Operators can typically become proficient with minimal training, and it is designed to minimize the need for highly skilled technicians.

Q: Can this machine be integrated with other woodworking equipment in a production line?

A: Absolutely. This CNC side drilling machine is designed to integrate seamlessly with other automated woodworking machinery such as CNC routers and edge banding machines, creating a streamlined and high-output production workflow.

Q: What are the key technical specifications of the Dual-Spindle CNC Side Drilling Machine?

A: Key specifications include a custom PLC control system, a USA-made laser positioning system with a 20-300mm range, dual high-power spindles, dual servo motors for precise movement, barcode scanning and laser positioning drilling modes, and a heavy-duty welded steel frame.

Q: What kind of maintenance does this machine require?

A: The machine is designed for durability and low maintenance. It features a smart auto-lubrication system for moving parts and an independent oil-water separation air filter to protect pneumatic components. Regular cleaning and adherence to the maintenance schedule outlined in the user manual are recommended.

Q: What are the primary applications of this Dual-Spindle CNC Side Drilling Machine?

A: Its primary applications include panel furniture manufacturing (cabinets, wardrobes, shelves), custom furniture production in woodworking shops, and integration into automated production lines for high-volume output.

Q: What drilling modes does this machine support?

A: The machine supports two drilling modes: barcode scanning for quick job setup using G-code IDs, and infrared laser positioning for accurate drilling based on workpiece markings.

Q: Does the machine come with a warranty?

A: Yes, the Dual-Spindle CNC Side Drilling Machine comes with a standard warranty. Please contact our sales team for specific warranty details and options.

Q: Can the power supply be customized for different regions?

A: The standard power supply is 380V/50Hz, but it can be customized some regions. Please confirm your specific power requirements with our sales team.

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.