CNC Six Sided Drilling Machine

Category:

Model:

Specs & Details:

- Advanced CNC Control System for Precision Drilling

- Six-Sided CNC Drilling Precision

- High-Efficiency CNC Drilling Output

- Enhanced Precision for Panel Furniture

Price Range :

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

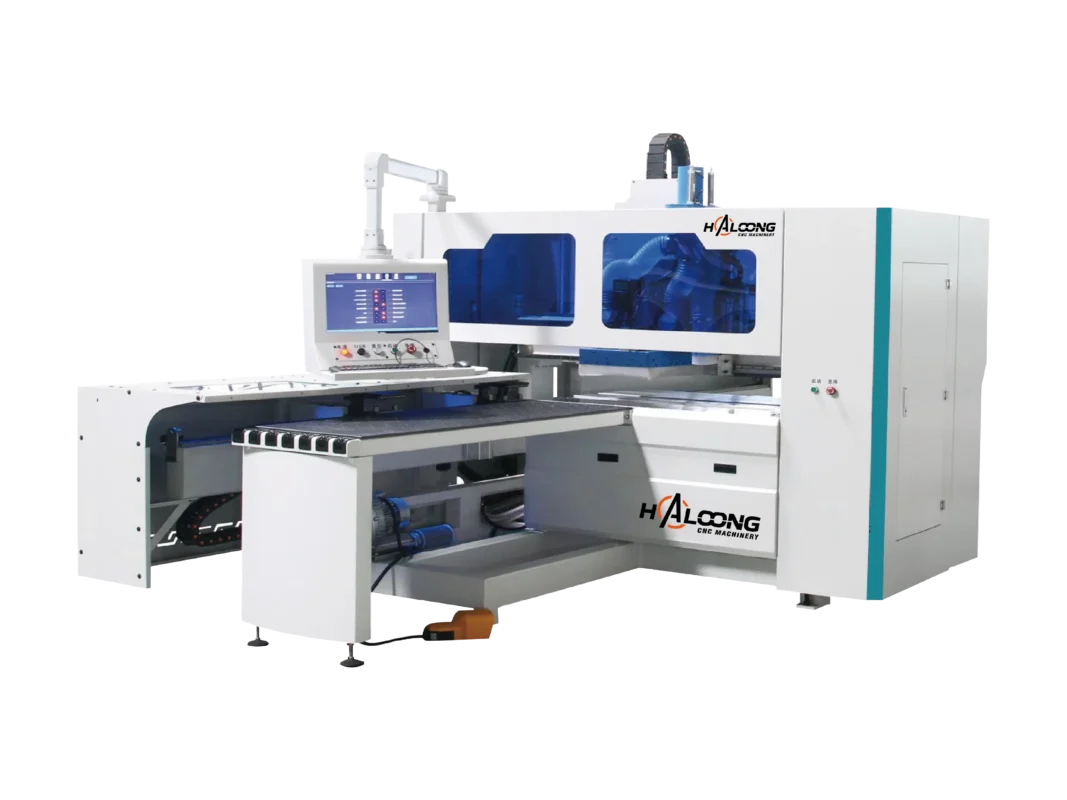

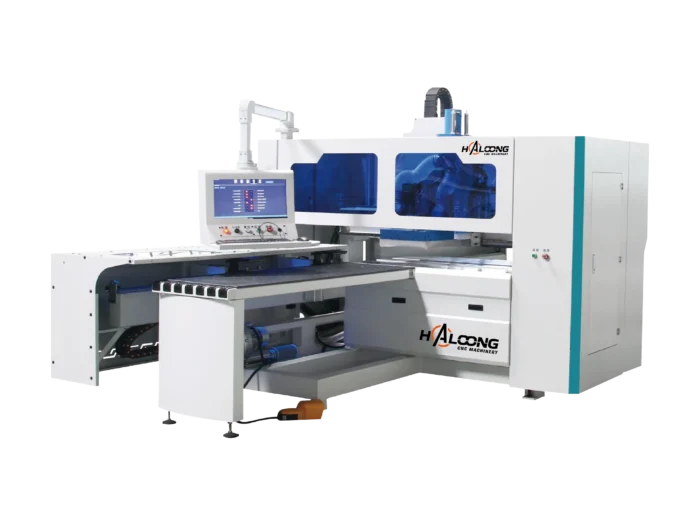

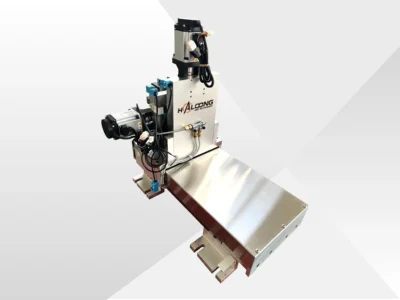

In the fast-evolving world of panel furniture production, efficiency and precision are paramount. The HALOONG CNC Six-Sided Drilling Machine is an advanced solution tailored for furniture manufacturers. With cutting-edge automation, it handles complex drilling and milling tasks across all six sides of a panel in one seamless operation. Whether you’re crafting cabinets, office furniture, or bespoke designs, this machine enhances your workflow with speed, accuracy, and simplicity.

This CNC drilling machine is specifically engineered for the panel furniture sector, providing manufacturers with a powerful tool to enhance their production lines.

Product Overview

The HALOONG CNC Six-Sided Drilling Machine revolutionizes traditional furniture manufacturing. It consolidates multiple processes—vertical drilling, cutting, edge banding, and side drilling—into just three steps: cutting, edge banding, and comprehensive six-sided drilling and milling. This streamlined approach boosts productivity while ensuring consistent precision for holes and grooves, making it a must-have for modern workshops.

Key CNC Drilling Features for Panel Furniture

Six-Sided CNC Drilling Precision

Drills and mills the top, bottom, and all four sides simultaneously, ensuring perfect alignment for connectors and dowels with no misalignment.

High-Efficiency CNC Drilling Output

Automated CNC technology completes complex patterns in a single cycle, surpassing traditional single-sided machines.

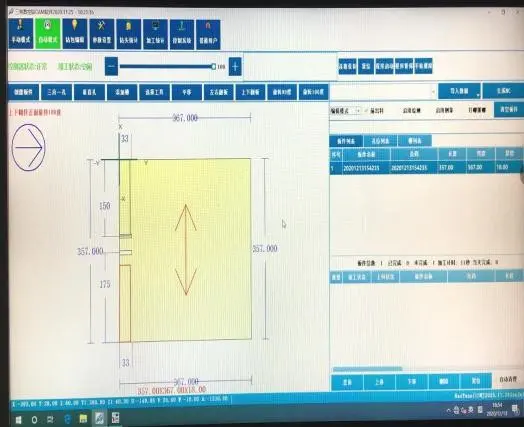

User-Friendly Interface

Features an intuitive screen with programmable settings, accessible even to novice operators.

Compact Design for Panel Furniture Workshops

- Measures 4800 mm × 2750 mm × 2300 mm, fitting easily into any workspace.

- Wide platen coverage reduces vibration, protecting panels and maintaining accuracy.

Enhanced Precision for Panel Furniture

- Multiple pressure rollers ensure consistent accuracy across various panel types.

- A standard pressure valve guarantees uniform hinge hole depths.

Compared to conventional drills requiring multiple setups, HALOONG’s six-sided capability saves time, reduces errors, and delivers superior results every time.

Applications in Panel Furniture Manufacturing

This machine is ideal for panel furniture manufacturing, excelling in:

Drilling for Three-in-One Connectors

Precise hole placement for seamless assembly.

Horizontal Grooving

Accurate slots for shelving and panels.

Custom Drilling Patterns

Handles specialized drilling needs with precision.

It integrates effortlessly with a CNC cutting machine: after cutting, all drilling and grooving tasks are completed in one pass.

Technical Specifications

The technical specifications below highlight the advanced capabilities of this CNC drilling machine, designed to meet the rigorous demands of panel furniture manufacturing.

| Parameter | Specification |

|---|---|

| X-axis travel | 4200 mm |

| Y-axis travel | 1800 mm |

| Z-axis travel | 250 mm |

| Workpiece length | 150 – 3050 mm |

| Workpiece width | 40 – 1200 mm |

| Workpiece thickness | 10 – 60 mm |

| Maximum processing dimension | 90 mm |

| Minimum processing dimension | 100 mm |

| Maximum X-axis speed | 135 m/min |

| Maximum Y-axis speed | 100 m/min |

| Maximum Z-axis speed | 30 m/min |

| Upper vertical drills | 5+7×2 |

| Upper horizontal drills | (X2×2, Y2×2)×2 |

| Lower vertical drills | 9 |

| Drill group power | 2.2 kW × 3 |

| Routing spindle speed | 18000 rpm |

| Routing spindle power | 3.5 kW × 2 |

| Workbench height | 900 mm |

| Main dust collection port diameter | 125 mm |

| Total power | 23.5 kW |

| Operating voltage | 380V 50Hz |

| Working air pressure | 0.6 – 0.8 MPa |

| Overall dimensions | 4800 mm × 2750 mm × 2300 mm |

Main Configuration

| Part Name | Reference Picture | Description of components |

|---|---|---|

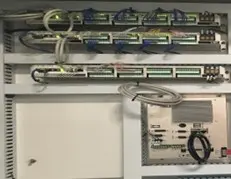

| Electrical and electric boxes |

| Brand: Schneider( France)

According to the European CE standards, the whole machine production, wiring, all line number identification is clear, the line is clear,random with circuit diagram, machine failure,trouble shooting inspection line is simple and convenient. |

| Main spindle |  | Brand: Changchuan 3.5 KW Air-cooled high-speed spindle * 2 speed :18000 rpm/min; |

| Guide rail and slider |  | Brand: Hiwin(Taiwan ) Good dustproof performance, high precision, heavy load and long service life. |

| Transmission |   | Special custom imported high precision 2 M helical bar, imported high precision reducer, large and stable transmission force, Z shaft using ball wire rod transmission. |

| Drive and Motor |   | High efficiency energy saving absolute value servo Low noise and high speed torque. Built-in precision bearing, large torsion, long working time, high resolution and accurate positioning. |

| Frequency converter |  | The low frequency output torque is large, the motor operation noise is small, the operation balance, the speed precision is high. |

| Control software |  | Brand: LNC + Sunvega The man-machine interface is friendly, easy to operate, scientific system algorithm and fast response time. |

| Gas storage tanks |  | High-end machines are equipped with gas cylinders to ensure stable air pressure, in case the machine pressure instability caused by the normal operation of the equipment, so that the equipment work more stable. |

| Drill kits |  | Brand:CC/Putin |

| Trailer chain |  | Adopt high flexible cable towing chain, excellent dustproof, anticorrosion, anti-static performance, support 150 degree bending,effectively protect cable. |

| Lubricating system |  | Lubrication, maintain mechanical accuracy and mechanical service life. |

These premium components ensure that the HALOONG CNC Six-Sided Drilling Machine delivers consistent and precise results, essential for high-quality panel furniture production.

System and Operation

Advanced CNC Control System for Precision Drilling

Scan codes to retrieve processing data instantly, accelerating production scheduling.

Flexible Compatibility

Supports CAD/CAM imports and formats like DXF, MPR, and XML.

Output Flexibility

Offers front or rear discharge options to match your setup.

Durable Worktable

Phenolic resin surface resists wear and deformation for lasting precision.

With these features, the machine not only simplifies operations but also maximizes the efficiency of CNC drilling processes in panel furniture manufacturing.

Maintenance Guidelines

Routine Care

- Regular Cleaning: Remove wood chips and dust from the machine and collection system.

- Spindle Inspection: Check periodically to ensure drilling accuracy.

- Software Updates: Install updates for improved performance and new features.

Adhering to these maintenance practices will help maintain the machine’s performance, ensuring it continues to produce precise and efficient results for panel furniture applications.

Why Choose HALOONG?

The HALOONG CNC Six-Sided Drilling Machine offers unmatched precision, automation, and efficiency in a compact, smart design. It’s perfect for manufacturers aiming to elevate quality and output, from small workshops to large-scale facilities. Choose HALOONG and step into the future of furniture production—where innovation meets excellence.

By choosing HALOONG, manufacturers invest in a future-proof solution that leverages the latest in CNC drilling technology to stay ahead in the competitive panel furniture market.

- Advanced CNC Control System for Precision Drilling

- Six-Sided CNC Drilling Precision

- High-Efficiency CNC Drilling Output

- Enhanced Precision for Panel Furniture

Complete The Form To Request A Quote Today!

FAQ

Q: What is a CNC six-sided drilling machine?

A: A CNC six-sided drilling machine is a computer-controlled device used in woodworking, particularly for panel furniture production. It can drill holes and perform milling operations on all six sides of a panel in a single setup, enhancing efficiency and precision.

Q: How does it improve my production process?

A:This six-sided CNC drilling machine drills all sides at once, saving time and ensuring accuracy for connectors and dowels, boosting efficiency.

Q: How does it compare to traditional drills?

A:Unlike single-sided drills, this automated woodworking tool processes all six sides in one pass, reducing labor and enhancing precision with CNC automation.

Q: What maintenance does this CNC equipment require?

A:Routine cleaning, spindle checks, and software updates keep this six-sided CNC drilling machine running smoothly with minimal effort.

Q: How does the HALOONG machine improve efficiency in panel furniture manufacturing?

A: It improves efficiency by consolidating multiple processes into a single setup, reducing production steps, increasing processing speed, and minimizing downtime through automation, which is crucial for panel furniture production.

Q: Can the machine handle different sizes of panels?

A: Yes, it can process panels from 150 mm to 3050 mm in length, 40 mm to 1200 mm in width, and 10 mm to 60 mm in thickness, making it versatile for various panel furniture needs.

Q: Is the machine easy to operate?

A: Yes, it features an intuitive screen interface and user-friendly LNC and Sunvega control systems, with comprehensive training provided, making it accessible even for operators with minimal experience.

Q: What software does the machine use?

A: It uses the LNC control system paired with Sunvega software for reliable CNC control and advanced design capabilities, ensuring seamless integration with design workflows.

Q: Is there customer support available?

A: Yes, HALOONG offers comprehensive customer support, including technical assistance, training, and after-sales service to ensure smooth operation

Q: Can the machine be integrated with other production equipment?

A: Yes, it is designed to integrate seamlessly with other equipment like CNC cutting machines and edge banding machines for a streamlined production line, enhancing overall efficiency.

Q: What file formats does the machine support for importing designs?

A: It supports DXF, MPR, XML, and other formats, allowing easy integration with popular CAD/CAM software used in the industry.

Q: What makes the HALOONG CNC Six-Sided Drilling Machine stand out from competitors?

A: It stands out due to its advanced six-sided processing, high-speed and precision operations, energy-efficient servos, premium components like Hiwin and Schneider, intuitive controls, compact design, and excellent customer support, making it a top choice for panel furniture manufacturers.

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

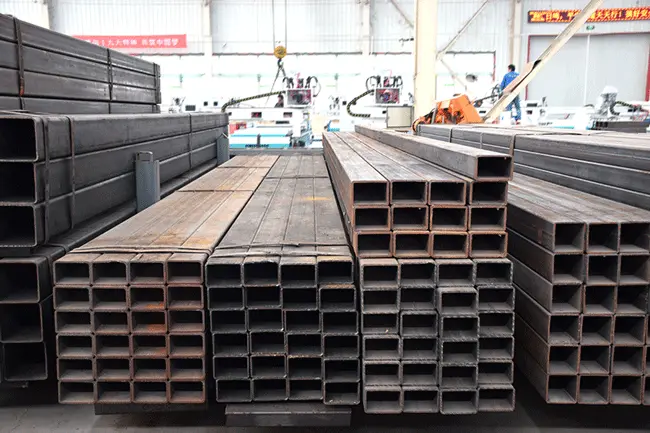

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.