HALOONG Automatic Loading and Unloading CNC Cutting Furniture Production Line

Category:

Model:

Specs & Details:

- Intelligent Loading and Unloading

- Efficient and Precise Panel Cutting

- Automatic Tool Changer

- Advanced Control System

Price Range :

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

The HALOONG CNC automatic loading and unloading system CNC panel production line is the ideal solution for modern panel furniture manufacturing. This production line integrates automatic loading, CNC panel cutting, and automatic unloading functions, automating the production process. This significantly improves production efficiency, reduces labor costs, and ensures processing accuracy. Whether for kitchen cabinets, wardrobes, office furniture, or custom furniture, HALOONG helps you handle it with ease and enhance your core competitiveness.

Detailed Description

The HALOONG automatic loading and unloading system CNC panel production line typically consists of the following three main parts:

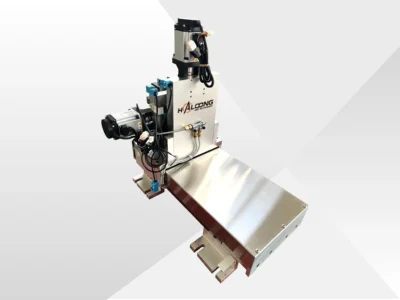

Automatic Height-Adjusting Lifting Platform (Automatic Loading System):

This is used to stack whole boards to be processed. The lifting platform can automatically adjust its height to ensure the boards are always in the optimal picking position.

CNC Straight-Line Automatic Tool Changer Machining Centre (or optional CNC Four-Spindle Nesting CNC Router / CNC Rotary Automatic Tool Changer Machining Centre):

This serves as the core processing unit of the production line and features automatic board gripping and automatic pushing functions. Upon receiving program code instructions, the machining centre will automatically move the suction cup grippers to pick up the uppermost whole board from the lifting platform and place it on the vacuum adsorption table. Through pop-up positioning cylinders, the whole board can be quickly and accurately aligned to the table’s zero point. Subsequently, it will start to call the matched tools according to the G-code instructions for operations such as carving, drilling, grooving, and cutting.

Unloading Platform with Belt Drive and Infrared Position Detection (Automatic Unloading System):

This is used to receive the processed workpieces. When the pushing arm pushes the workpiece to the unloading platform, the infrared detection device will sense the workpiece and activate the transmission device to automatically transport the workpiece to the position required for the next process.

Automatic Loading and Unloading Process:

A forklift stacks the whole boards to be processed on the automatic height-adjusting lifting platform. After receiving program instructions, the CNC machining centre automatically grips the board and places it on the vacuum table for processing. Once processing is complete, the pushing arm pushes the workpiece to the automatic unloading platform. Simultaneously, the machining centre continues to grip the next board from the lifting platform, achieving a continuous and uninterrupted automated production cycle until all program instructions are executed.

Core Functions Of ALU Furniture Production Line:

Intelligent Loading and Unloading:

Equipped with an advanced vacuum adsorption system and an automatic pushing device, this system achieves automatic loading of boards and automatic unloading after processing, significantly reducing manual intervention and improving production efficiency.

Efficient and Precise Panel Cutting:

It can perform fast and precise board cutting, drilling, and grooving according to pre-designed drawings.

Automatic Tool Changer:

Accommodates 4 to 20 tools (depending on the model), eliminating the need for manual replacement and meeting various process requirements such as door panel carving, drilling, grooving, cutting, and concealed connection processing.

Irregular Shape Cutting:

Supports the cutting of various complex irregular patterns, meeting personalized customization needs.

Board Optimization:

Equipped with professional board optimization software to maximize board utilization and reduce production costs.

Resume After Breakpoint:

Features power-off and tool breakage resume functions, effectively avoiding material waste due to unexpected situations.

Vacuum Adsorption Table:

Adopts a partitioned vacuum system controlled by solenoid valves to ensure that wooden boards of different sizes and shapes are firmly fixed during processing.

Advanced Control System:

Equipped with an advanced CNC controller and user-friendly software for easy programming and monitoring operations, supporting G-code and other format instructions for control, and easy integration with design software.

Significant Advantages Of HALOONG Automatic Loading and Unloading Furniture Production Line

Choosing the HALOONG CNC automatic loading and unloading CNC panel production system will provide you with the following significant advantages:

Significantly Improved Efficiency:

The automatic loading and unloading system frees up manpower and enables continuous production, increasing efficiency several times over.

Reduced Costs:

No manual handling of boards is required, significantly reducing the physical exertion of workers, and allowing one person to operate the machine easily.

Improved Product Quality:

Precise processing ensures the accuracy and consistency of product dimensions, reducing rework.

Optimized Board Utilization:

Professional optimization software minimizes waste, reducing material loss.1

Simple and Easy to Learn Operation:

Equipped with a user-friendly operating interface and a comprehensive training system, making it easy to get started.

Safe and Reliable:

Multiple safety protection measures ensure the safety of operators and equipment.

- Enhances the factory’s ability for continuous operation and continuous processing demands.

Wide Applications

The HALOONG CNC automatic loading and unloading system is widely used in the following industries and scenarios:

- Panel Furniture Production: Kitchen cabinets, wardrobes, bookcases, TV cabinets, etc.

- Office Furniture Production: Office desks, conference tables, filing cabinets, etc.

- Custom Furniture Production: Customized furniture products meeting individual needs.

- Wooden Door Production: Solid wood composite doors, molded doors, etc.

- Other Wood Product Processing: Such as display cabinets, handicrafts, sign making, and decorations.

- Prototype Development: Rapidly produce wooden prototypes for new product design.

Why Choose HALOONG?

HALOONG is committed to providing high-quality and high-efficiency automated solutions for furniture manufacturing enterprises. Our CNC automatic loading and unloading CNC system has the following features:

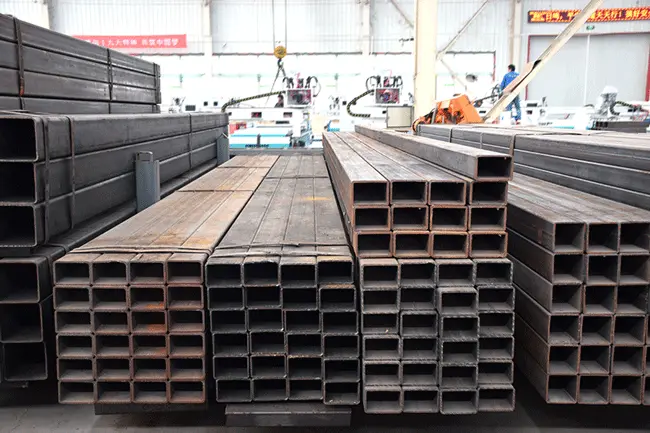

- Sturdy and Durable Machine Body Structure: Adopts a heavy-duty bed and gantry structure design welded from thick-walled steel tubes, effectively reducing vibration and ensuring the stability and processing accuracy for long-term heavy-load work.

- High-Precision Transmission System: Equipped with high-precision linear guides, precision gear racks, and high-performance servo drive systems to ensure smooth equipment operation, precise positioning, fast processing speed, and low noise.

- Intelligent Automatic Lubrication System: Automatically lubricates the guide rails and gear racks at regular intervals and in precise quantities, reducing manual maintenance and extending the service life of the equipment.

- Comprehensive After-Sales Service System: We provide comprehensive pre-sales consultation, installation and commissioning, and after-sales technical support to ensure the smooth operation of your production.2

- Customizable Solutions: HALOONG can provide customized automatic loading and unloading CNC furniture production lines according to your specific production needs.

Main Technical Parameters

Parameter | Specification (Common Models) |

|---|---|

Worktable Size | 4’x8′ (1220×2440 mm), 4’x9′ (1220×2800 mm), Customizable in other sizes |

Max Running Speed | 80 m/min |

Max Processing Speed | 20 -30m/min |

Spindle Power | 9.0 kW / 11.0 kW / 12.0 kW ( Optional) |

Spindle Speed | 18,000-24,000 rpm |

Tool Magazine Capacity | 4-20 tools (Inline or Carousel) |

Drive System | Servo Motor (Yaskawa/Delta) |

Control System | LNC / SYNTEC |

Positioning Accuracy | ±0.05 mm (±0.002 in) |

Repeat Positioning Accuracy | ±0.02 mm |

Power Requirement | 380V/50Hz |

Vacuum Pump Power | 7.5 kw/9kw/11kw |

(Please note: The above parameters are for reference only, and the specific parameters are subject to the actual equipment. HALOONG can provide customized services according to your special needs.)

Act Now to Revolutionize Your Furniture Production Line

Contact HALOONG now to learn more about our automatic loading and unloading CNC panel production line and get your exclusive customized solution! Let automation boost your furniture production and achieve a dual improvement in efficiency and quality!

- Intelligent Loading and Unloading

- Efficient and Precise Panel Cutting

- Automatic Tool Changer

- Advanced Control System

Complete The Form To Request A Quote Today!

FAQ

Q: What is an automatic loading and unloading CNC cutting furniture production line?

A: This system integrates automated material loading, high-precision CNC cutting, and efficient unloading of finished furniture components, streamlining the entire production process.

Q: What are the main benefits of using this system?

A: The key benefits include increased production efficiency, reduced labor costs, improved accuracy and product quality, maximized material utilization, and enhanced intelligent manufacturing capabilities.

Q: What types of furniture can this production line manufacture?

A: This system is versatile and can be used for panel furniture like wardrobes, cabinets, bookcases, office furniture, custom furniture, wooden doors, showcases, and more.

Q: Is this system suitable for small businesses or only large-scale production?

A: While highly efficient for large volumes, the system’s flexibility and customization options can also benefit smaller businesses looking to improve efficiency and quality.

Q: What is the typical lifespan of this equipment?

A: With proper maintenance, this robustly built system is designed for long-term, heavy-duty operation. The exact lifespan depends on usage and maintenance practices.

Q: What CNC control system is used in this production line?

A: We typically use well-known and reliable CNC control systems like LNC or SYNTEC, but other options may be available based on specific requirements.

Q: What is the maximum processing speed of the machine?

A: The maximum processing speed varies by model but generally ranges from 20-30 meters per minute. Please refer to the technical parameters of specific models.

Q: What materials can this system process?

A: The system is designed for processing various types of wood-based panels, including MDF, particleboard, plywood, and solid wood composites.

Q: What is the power consumption of this production line?

A: Power consumption varies depending on the specific configuration and model. Detailed power specifications are available in the technical parameters.

Q: What are the space requirements for installing this production line?

A: Space requirements depend on the specific configuration and the inclusion of optional modules. We provide detailed layout plans based on your chosen system.

Q: Is the system easy to operate?

A: Yes, the system features a user-friendly interface and intuitive operating software. We also provide comprehensive training to ensure operators can quickly learn to use the equipment.

Q: What kind of maintenance is required for this production line?

A: Regular maintenance includes cleaning, lubrication, checking for wear and tear, and following the recommended maintenance schedule provided in the user manual.

Q: What happens if there is a technical issue or breakdown?

A: We offer comprehensive after-sales service, including technical support, remote diagnostics (if possible), and on-site maintenance services.

Q: Can this production line be customized to meet our specific needs?

A: Yes, we offer flexible customization services to tailor the automatic loading and unloading CNC cutting furniture production line to your specific requirements and production goals.

Q: What are the available spindle configurations?

A: We offer options including CNC straight-line automatic tool changers, CNC four-spindle nesting machines, and CNC rotary automatic tool changers.

Q: What is the lead time for ordering and receiving this production line?

A: Lead times vary depending on the specific configuration and customization requirements. We will provide an estimated lead time upon receiving your detailed specifications.

Q: What is the warranty period for this equipment?

A: We typically offer a warranty period on our equipment. Please contact us for specific warranty details.

Q: How can I get a quote for this production line?

A: You can contact us through the inquiry form on our website, email us directly, or call our sales team. We will be happy to discuss your needs and provide a personalized quote..

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.