Advanced 4-Axis Rotary CNC Engraving Machine

Category:

Model:

Specs & Details:

- Unmatched Precision on Curved & Complex Surfaces

- 4-axis control system

- Heavy-Duty Construction for Lasting Reliability

Price Range :

$19,999.00 – $24,999.00Price range: $19,999.00 through $24,999.00

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

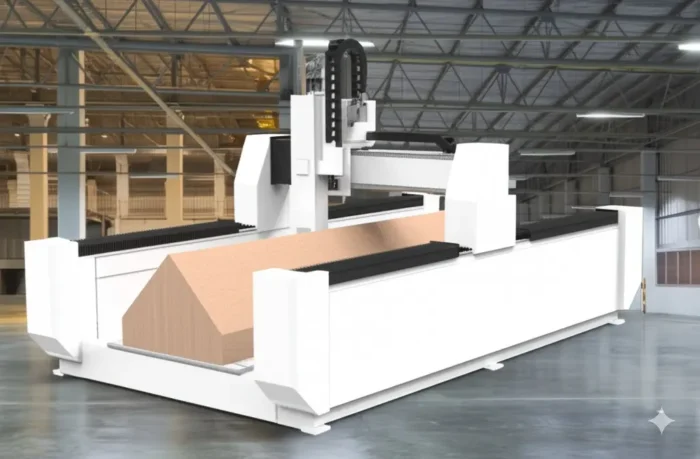

The Four-Axis Rotary Head CNC Engraving Machine can be used for precision engraving on curved surfaces. Featuring a swiveling spindle that rotates around the Y-axis and four-axis CNC control, It’s a compact, eco-friendly precision CNC engraving tool ideal for woodworking professionals and furniture manufacturers.

High-Performance CNC Solution for Complex 3D Woodworking

Elevate your craftsmanship with our state-of-the-art 4-Axis Rotary CNC Engraving Machine. Engineered for artisans, furniture manufacturers, and production facilities demanding exceptional accuracy on curved and irregular surfaces, this automated carving machine delivers powerful, precise, and efficient performance. Utilizing a sophisticated 4-axis control system (X, Y, Z + A Rotary Axis) and a high-frequency spindle, it expertly transforms intricate designs into reality on wood, composites, and more. Move beyond manual limitations and embrace a smart CNC solution designed to boost productivity and unlock complex design potential.

Why Choose Our 4-Axis Rotary CNC Engraving Machine?

Key Features & Benefits

Unmatched Precision on Curved & Complex Surfaces

The integrated A-axis rotary device enables precise machining on cylindrical and multi-sided workpieces. Combined with simultaneous 4-axis control, this machine excels where standard 3-axis routers fall short, delivering flawless results on pre-formed curves, furniture legs, statuary, and more. It features a spindle capable of ±90° swivel around the Y-axis, allowing for intricate angled machining.

High-Speed Performance & Productivity

Equipped with a powerful spindle capable of speeds up to 24,000 RPM, this machine carves complex patterns rapidly. CNC automation ensures consistent quality and dramatically reduces cycle times compared to manual methods, streamlining your workflow.

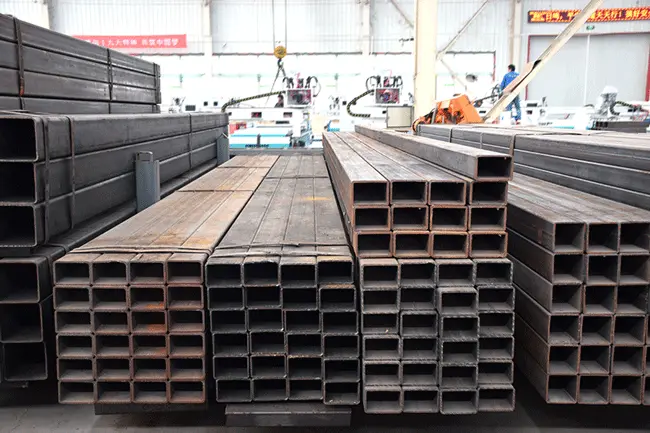

Heavy-Duty Construction for Lasting Reliability

Built on a robust, heavy-duty frame using high-quality components, this automated CNC carving machine is engineered for durability and sustained performance in demanding industrial environments, ensuring years of reliable operation.

Versatile Material Compatibility

Ideal for a wide range of materials including solid wood, bent wood, MDF, plywood, plastics, composites, and non-ferrous metals . A true workhorse for diverse woodworking and engraving applications.

Advanced Control & Compatibility

Features a stable and user-friendly Advanced CNC Control System. It readily accepts standard G-code generated from leading CAM software packages (e.g., Vectric, ArtCAM, Fusion 360), ensuring seamless integration into your design process.

Technical Specifications

Detailed Machine Parameters

| Feature | Details |

|---|---|

| Working Area (X, Y) | 1500 x 3000 mm (Approx. 5′ x 10′) |

| Z-Axis Travel | Provided per configuration |

| A-Axis (Rotary) | Provided per configuration |

| Axis Motion System | X, Y, Z + A (Rotary Axis) |

| Spindle Type | High-Frequency Spindle |

| Spindle Speed | Up to 24,000 RPM |

| Spindle Power | 9 kW (Approx. 12 HP) |

| Spindle Swivel Range | ±90° around Y-Axis |

| Drive System | High-Precision Drive System |

| Control System | Advanced CNC Controller |

| Software Compatibility | Standard G-Code (Compatible with major CAM packages) |

| Machine Dimensions (LWH) | Approx. 3200 x 2000 x 1800 mm (126″ x 79″ x 71″) |

| Machine Weight | Approx. 2000 kg (4409 lbs) |

| Power Requirements | ( 380V/3Ph/50Hz) |

| Available Options | Dust Collection System, Automatic Tool Changer (ATC), etc. |

Key Applications & Industries

Where This Machine Excels

- Furniture Manufacturing: Perfectly suited for engraving intricate details on curved chair backs, legs, armrests, headboards, table edges, and ornate cabinet doors.

- Artistic Woodworking: Create complex 3D carvings, sculptures, reliefs, and detailed patterns on various wood species.

- Decorative Arts & Signage: Produce custom signs, architectural elements, decorative panels, and molds featuring curved or complex geometry.

- Musical Instruments: Engrave or shape instrument bodies (guitars, violins), necks, and other components requiring precise contours.

- Prototyping & Specialty Items: Ideal for creating models, custom jigs, and unique products with complex shapes.

Advantages Over Traditional & Basic CNC Methods

Why Upgrade?

- Beyond Manual Limits: Overcomes the speed, consistency, and precision limitations of manual carving, especially on complex shapes.

- Superior to 3-Axis: While versatile, standard 3-axis CNCs lack the crucial ability of this 4-axis rotary machine to easily machine multiple sides and true cylindrical or curved surfaces without complex setups.

- Complex Geometry Simplified: The combination of rotary capability and precise multi-axis control makes producing designs previously deemed too difficult or time-consuming highly efficient.

- Enhanced Productivity & ROI: Faster cycle times, reduced labor requirements, and consistent, high-quality output lead to greater throughput and a faster return on investment.

Ready to Revolutionize Your Curved Surface Engraving?

Get Started Today!

Discover the precision, speed, and versatility of the 4-Axis Rotary CNC Engraving Machine. It’s more than just woodworking equipment; it’s a smart CNC solution engineered to elevate your production capabilities.

Contact us today for a personalized quote, detailed specifications, or to schedule a virtual or in-person demonstration. See firsthand why this machine is the preferred choice for professionals tackling complex curved material projects.

- Unmatched Precision on Curved & Complex Surfaces

- 4-axis control system

- Heavy-Duty Construction for Lasting Reliability

Complete The Form To Request A Quote Today!

FAQ

General Questions

- What is a 4-Axis Rotary CNC Engraving Machine?A 4-axis rotary CNC engraving machine is an automated carving machine that utilizes four axes of motion (X, Y, Z linear axes and an A rotary axis) to perform precise and intricate engravings and carvings on various materials, particularly on curved or cylindrical surfaces.

- What materials can this machine engrave?This machine is ideal for a wide range of materials including solid wood, bent wood, MDF, plywood, plastics, composites, and non-ferrous metals (with appropriate setup and tooling).

- What are the main benefits of using this machine?The key benefits include unmatched precision on curved surfaces, high-speed performance and productivity, heavy-duty construction for reliability, versatile material compatibility, and advanced control with compatibility with industry-standard CAM software.

Technical Questions

- What is the working area of the machine?The standard working area (X, Y) is 1500 x 3000 mm (approximately 5′ x 10′). Custom sizes may be available depending on the configuration.

- What is the capacity of the rotary axis (A-axis)?The maximum diameter and length capacity of the rotary axis will vary depending on the specific machine configuration. Please refer to the specifications of the model you are interested in.

- What is the spindle speed and power of the machine?The machine is equipped with a high-frequency spindle capable of speeds up to 24,000 RPM and a power of 9 kW (approximately 12 HP).

- What is the spindle swivel range?The spindle can swivel ±90° around the Y-axis, allowing for complex angled machining operations.

- What type of control system does the machine use?The machine features an Advanced CNC Control System. The specific brand and model may vary; please refer to the details of the configuration you are considering.

- What software is compatible with the machine?The machine accepts standard G-code, which is generated by most leading CAM software packages such as Vectric, ArtCAM, and Fusion 360.

- What are the dimensions and weight of the machine?The approximate dimensions of the machine are 3200 x 2000 x 1800 mm (126″ x 79″ x 71″). The approximate weight is 2000 kg (4409 lbs). These are for the standard configuration.

- What are the power requirements for this machine?Power requirements will vary based on the specific configuration. Common options 380V/3Ph/50Hz. Please confirm the exact requirements for your chosen model to ensure facility compatibility.

Operational Questions

- Is the machine difficult to operate?While it’s an advanced machine, the Advanced CNC Control System is designed to be user-friendly. Familiarity with CNC operation and CAM software is recommended.

- What kind of maintenance is required for the machine?Regular maintenance includes cleaning, lubrication of moving parts, checking and tightening connections, and periodic inspection of the spindle and other critical components. Specific maintenance schedules will be provided in the machine’s manual.

Application-Specific Questions

- Can this machine be used for furniture manufacturing?Yes, it is perfectly suited for engraving intricate details on curved chair backs, legs, armrests, headboards, table edges, and ornate cabinet doors.

- Is this machine suitable for artistic woodworking?Absolutely! It can create complex 3D carvings, sculptures, reliefs, and detailed patterns on various wood species.

- Can this machine engrave musical instruments?Yes, it can be used to engrave or shape instrument bodies (guitars, violins), necks, and other components requiring precise contours.

Comparison Questions

- What is the difference between a 3-axis and a 4-axis CNC machine?A 3-axis CNC machine can move along the X, Y, and Z axes. A 4-axis machine adds a rotary axis (A-axis), allowing the workpiece to be rotated during the machining process. This enables machining on multiple sides and true cylindrical or curved surfaces without manual repositioning.

- What are the advantages of this machine over manual methods?This machine offers significantly higher speed, accuracy, and consistency compared to manual carving methods. It can handle complex designs that would be difficult or impossible to achieve manually and greatly improves productivity.

Purchasing and Options Questions

- How do I get a quote for this machine?To get a quote, please contact our sales team with your specific requirements and any desired options. They will be able to provide you with detailed pricing and lead times.

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.