Industrial-Grade CNC Router: High-Performance Solution for Modern Manufacturing

Category:

Model:

Specs & Details:

- High-rigidity and stable structure

- Precise and efficient drive system

- Intelligent control and automation features

- Broad compatibility with various materials and processes

Price Range :

$29,999.00 – $35,999.00Price range: $29,999.00 through $35,999.00

/ Set based on the configuration

Purchase & After-sales Service:

- Online (PayPal, Trade Assurance) / Offline (T/T, Debit & Credit Cards)

- 100 Units in Stock Available for Sale Every Month

- One-Year Limited Warranty for Entire Machine (Extended Warranties Available for Major Parts)

- Free Lifetime Technical Support for End-Users & Dealers

VIDEOS

This industrial-grade CNC router is engineered as a high-performance processing solution tailored for today’s manufacturing demands. Offering an exceptional cost-performance ratio and versatile applications across diverse industries, this large CNC cutting machine empowers businesses with significant large-scale production capabilities. Designed to meet the stringent requirements of high precision, high efficiency, and high-volume production, it is ideally suited for sectors including aerospace, automotive, construction, furniture production, and general manufacturing. By integrating advanced engineering, premium materials, and intelligent technology, this equipment provides users with superior processing power, flexible customization options, and long-term reliability.

Key Features and Benefits

1. Robust Structure and Stability

- Heavy-Duty Frame: The foundation of this large CNC cutting machine is its robust gantry structure, crafted from high-strength welded steel, ensuring unparalleled stability during high-speed machining and when handling substantial workpieces.

- Advanced Vibration Reduction: Equipped with state-of-the-art vibration damping pads and reinforced crossbeams, the machine minimizes vibrations during rapid cutting, guaranteeing exceptional processing accuracy.

2. Precision Drive and Efficient Power

- High-Performance Servo Motors: Featuring closed-loop servo motors, the system delivers swift dynamic response and a precise positioning accuracy of ±0.03mm.

- Reliable Transmission System: The X and Y axes utilize a high-precision rack and pinion drive, while the Z-axis is equipped with a ball screw mechanism, ensuring smooth, dependable operation and an extended lifespan.

- Powerful Spindle Options: Comes standard with an 11kW spindle, with options for higher power ratings to suit various material processing needs. Achieves speeds up to 24,000 RPM for efficient high-speed machining.

3. Intelligent Control and Automation

- Advanced CNC Controller: Integrated with a sophisticated multi-axis linkage CNC controller, supporting both standard G-code and M-code programming. Seamlessly compatible with leading CAD/CAM software such as AutoCAD, SolidWorks, ArtCAM, and more.

- Fast Automatic Tool Changer (ATC): Boasts a servo-driven carousel-style tool magazine with a 10-20 tool capacity automatic tool changer (ATC), enabling rapid tool changes, minimizing downtime, and maximizing productivity.

- Efficient Workpiece Positioning: Features integrated pneumatic workpiece positioning devices for quick and accurate material setup, further streamlining production.

- Enhanced Automation (Optional): For even greater efficiency, an optional automatic loading and unloading system is available to minimize manual intervention in the production cycle.

4. Versatile Processing Capabilities

- Wide Material Compatibility: Capable of processing a diverse range of materials, including wood, plastics, aluminum, steel, and composite materials, for cutting, milling, engraving, and drilling applications. Handles a maximum material thickness of up to 150 mm (4 inches).

- Comprehensive Processing Technology: Offers both 2D/3D processing capabilities, making it ideal for creating intricate geometric shapes, manufacturing molds, and performing detailed engraving.

- Secure Workpiece Holding: Equipped with a pneumatic vacuum table with segmented zones and supplementary pressure roller devices to securely hold workpieces of varying sizes and shapes during machining operations.

5. User-Centric Design and Safety

- Intuitive Operation Interface: Features a multi-language, large-size display interface designed for ease of use and a minimal learning curve. Supports convenient data transfer via USB, WiFi, and Ethernet.

- Comprehensive Safety Features: Includes a readily accessible emergency stop button and other safety mechanisms.

- Simplified Maintenance: The modular design combined with a centralized lubrication system simplifies routine maintenance tasks, contributing to the equipment’s extended operational life.

- Clean Working Environment (Optional): An optional high-performance dust collection system is available to maintain a clean and safe workspace, particularly beneficial for woodworking applications.

Technical Specifications

| Parameter | Specification Description |

|---|---|

| Spindle Power | 11kW (Optional) |

| Spindle Speed | 24,000 RPM (Adjustable) |

| Drive System | Closed-loop Servo Motor |

| Transmission | X/Y Axis: High-precision Rack and Pinion; Z Axis: Ball Screw |

| Linear Guides | Heavy-duty Linear Guide Rails (30mm wide) |

| Controller | Intelligent CNC Controller (Supports 3-Axis Linkage Expansion) |

| Table Size | Customizable from 6×12 ft (1.83 x 3.66 meters) to 10×50 ft (3.05 x 15.24 meters) |

| Z-Axis Travel | 300mm (11.8 inches) (Optional 400mm (15.7 inches)) |

| Gantry Clearance | 250mm (9.8 inches) (Optional up to 18 inches (457mm)) |

| Positioning Accuracy | ±0.03mm |

| Repeatability | ±0.02mm |

| Max. Cutting Speed | 25 m/min (980IPM) |

| Tool Magazine Capacity | 10 Positions (Optional 10-20 Positions) |

| Vacuum Pump Power | 7.5kW (Optional Dual Pumps or Other Power) |

| Power Requirements | 380V, 3-Phase, 50Hz |

| Machine Dimensions (L x W x H) | 8300mm x 3350mm x 2450 mm (326inches x 131 inches x 96inches)Customizable |

| Machine Weight | Varies by Configuration |

Industry Applications

This CNC router is a versatile asset for a wide range of industries, meeting diverse processing needs:

- Aerospace: Ideal for precision machining of lightweight alloys, carbon fiber composites, and other high-precision parts.

- Automotive Manufacturing: Efficiently produces vehicle body panels, interior components, molds, and prototypes.

- Construction Industry: Excels in cutting prefabricated components, decorative panels, and large-size wood for various building applications.

- Furniture Production: Perfect for intricate complex engraving, efficient nesting cutting to optimize material usage, and high-volume mass production of furniture components.

- General Manufacturing: Suitable for a multitude of processing tasks involving both metal processing and non-metal processing of various materials.

Core Advantages: Why Choose Our CNC Router?

- Unbeatable Cost-Effectiveness: Offers a comprehensive suite of standard features, delivering exceptional performance at a competitive price point.

- Exceptional Versatility: Highly adaptable to a broad spectrum of tooling and processing requirements, making it a truly multi-functional machine.

- Superior Large-Scale Production: Leveraging the automation capabilities inherent in a dedicated CNC cutting machine, it is perfectly suited to meet demanding high-volume production needs.

- Optimized Efficiency and Precision: Features a powerful spindle, rapid traverse speeds, and a closed-loop control system, ensuring both high efficiency and high precision in every machining operation.

- Highly Flexible Customization: Provides a wide array of customizable options, including various table sizes, spindle power ratings, automatic loading/unloading systems, and dust collection systems, to precisely align with individual customer requirements.

- Intelligent and User-Friendly: Boasts an intuitive user-friendly interface, significantly enhancing equipment management efficiency and providing a seamless operational experience.

Your Benefits: Investing in Excellence

- Maximize Production Efficiency: The automatic tool changer and optional automated loading/unloading systems minimize manual intervention, drastically reducing processing cycles and increasing overall throughput.

- Minimize Operating Costs: An energy-saving intelligent design and an easy-to-maintain structure contribute to lower energy consumption and reduced maintenance expenses, resulting in significant long-term cost savings.

- Gain a Competitive Edge: The machine’s high precision and diverse processing capabilities empower users to undertake more complex and demanding projects, thereby significantly enhancing their market competitiveness.

- Ensure Long-Term Reliability: A robust structure constructed with high-quality components guarantees stable and dependable operation even in demanding industrial environments, providing a long service life and a strong return on investment.

- Comprehensive Support and Peace of Mind: Benefit from our comprehensive after-sales service, including readily available technical support, ensuring a smooth integration and seamless operation of your equipment. We also offer a 1 year warranty on the machine for added assurance.

Conclusion: Unlock Your Manufacturing Potential

This industrial-grade CNC router represents a state-of-the-art processing solution, seamlessly integrating high-performance, multi-functional capabilities, and intelligent features. Beyond its cost-effective operation, inherent versatility, and substantial large-scale production capacity, its user-friendly design significantly enhances the overall user experience. Whether your business demands the precise machining of high-precision parts or requires efficient mass production solutions across sectors such as shipbuilding, automotive manufacturing, or furniture manufacturing, this machine delivers exceptional performance and unmatched flexibility, providing significant value and a sustainable competitive advantage.

- High-rigidity and stable structure

- Precise and efficient drive system

- Intelligent control and automation features

- Broad compatibility with various materials and processes

Complete The Form To Request A Quote Today!

FAQ

General Questions:

- What is this industrial CNC router primarily used for?

- This industrial CNC router is a high-performance processing machine designed for cutting, milling, engraving, and drilling various materials such as wood, plastics, aluminum, steel, and composites. It’s ideal for applications requiring high precision, efficiency, and large-scale production.

- Which industries is this CNC router suitable for?

- This CNC router is versatile and suitable for a wide range of industries, including aerospace, automotive manufacturing, construction, furniture production, and general manufacturing.

- What are the main advantages of using this CNC router?

- The main advantages include a high cost-performance ratio, multi-functional capabilities, large-scale production capacity, high efficiency and precision, flexible customization options, and an intelligent, user-friendly design.

Performance and Capabilities:

- What is the positioning accuracy of this CNC router?

- The positioning accuracy of this CNC router is ±0.03mm.

- What is the maximum spindle speed?

- The maximum spindle speed is 24,000 RPM, adjustable to suit different materials and processing requirements.

- What materials can this CNC router process?

- This router can process a wide range of materials, including wood, plastics, aluminum, steel, and composite materials.

- What is the maximum material thickness it can handle?

- This router can handle a maximum material thickness of up to 150mm (4 inches).

- What kind of processing can this machine perform?

- This machine offers comprehensive 2D and 3D processing capabilities, including cutting, milling, engraving, and drilling.

- What is the maximum cutting speed of this machine?

- The maximum cutting speed is 25 m/min (980 IPM).

Features and Technology:

- What type of CNC controller does it use?

- It is equipped with an intelligent multi-axis linkage CNC controller that supports G-code and M-code programming.

- Is it compatible with design software?

- Yes, it is compatible with a wide range of leading CAD/CAM software, including AutoCAD, SolidWorks, ArtCAM, and others.

- Does it have an automatic tool changer (ATC)?

- Yes, it features a servo-driven carousel-style tool magazine with a 10-20 tool capacity ATC for rapid tool switching.

- What is the function of the vacuum table?

- The pneumatic vacuum table with segmented zones and pressure rollers securely holds workpieces of various sizes and shapes during machining.

- Is there an option for an automatic loading and unloading system?

- Yes, an optional automatic loading and unloading system is available for enhanced automation.

- Is a dust collection system included?

- An optional high-performance dust collection system is available to maintain a clean and safe working environment.

Customization and Options:

- Can the table size be customized?

- Yes, the table size is customizable, with options ranging from 6×12 ft (1.83 x 3.66 meters) to 10×50 ft (3.05 x 15.24 meters).

- Can the spindle power be upgraded?

- Yes, higher spindle power options are available upon request.

- Are there other customization options available?

- Yes, other customization options may include different tool magazine capacities and additional features. Please contact our sales team for specific requirements.

Operation and Maintenance:

- Is the machine easy to operate? Yes, it features a multi-language, large-size display interface designed for intuitive operation and a low learning curve.

- Do you provide training for operating the machine? Yes, comprehensive after-sales service includes professional installation and thorough training.

- How easy is the maintenance of this CNC router? The modular design and centralized lubrication system simplify routine maintenance.

- What are the power requirements for this machine? The power requirement is 380V, 3-Phase, 50Hz.

Support and Warranty:

- What kind of after-sales service do you offer?

- We offer comprehensive after-sales service, including installation, training, and technical support.

- What is the warranty period for this CNC router?

- We offer a 1 year warranty on the machine.

- Where can I get technical support if needed?

Purchasing and Logistics:

- How can I get a quote for this CNC router?

- Please contact our sales team through our website or by phone to request a quote.

- What is the lead time for delivery?

- The lead time for delivery may vary depending on the configuration and your location. Please contact our sales team for an estimated delivery time.

- Do you offer installation services?

- Yes, professional installation services are included as part of our service.

Complete The Form To Request A Quote Today!

APPLICATIONS

INDUSTRIES

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object. Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals.

To learn more about the industry applications of HALOONG CNC machines, click here.

MATERIAL

Wood: natural wood, plywood, soft wood, hard wood, OSB、fiberboard, particle board, melamine board, LDF, MDF, chipboard

Plastic and rubber: acrylic, ABS, HDPE, PVC, LDPE, UHMW, resin, double-colored board, PP, EVA

Stone: granite, marble, slate, basalt, pebbles, ceramic, porcelain, natural and artificial stones

Soft metal: aluminum, brass, copper, mild steel

Composite: aluminum plastic composite, copper composite, titanium composite, zinc composite

To learn more about the material applications of HALOONG CNC machines, click here.

Quality control

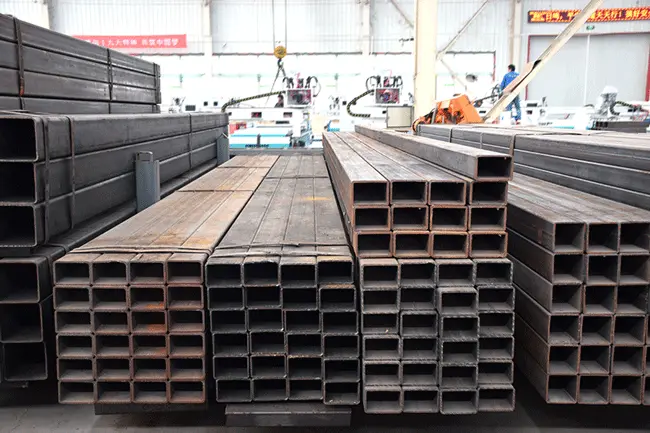

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Learn more why choose us

Reviews

There are no reviews yet.