Level Up Your CNC Router: A Guide to Automatic Tool Changer (ATC) & Drill Block Spindles | HALOONG CNC Spindle Guide Part 2

In Part 1 of our Spindle Knowledge series, we covered the fundamentals of water-cooled and air-cooled spindles. Now, let’s explore two more advanced options often found on higher-production CNC routers: the Automatic Tool Changing (ATC) spindle and the specialized Drilling Spindle, frequently incorporating a drill pack or drill block. These units are typically more complex and represent a larger investment, but they unlock significant efficiency gains.

The Power of Automation: ATC Spindles

An Automatic Tool Changing (ATC) spindle dramatically reduces downtime and manual intervention by allowing the CNC machine to swap cutting tools automatically during a job.

- How it Works: Instead of fixing a tool directly into the spindle, ATC systems use standardized tool holders (like HSK or ISO tapers). Each required tool is pre-loaded into its own holder. The ATC spindle has a sophisticated internal clamping mechanism that can grab and release these holders pneumatically. The tool change sequence involves precise movements and relies on compressed air for actuation – including clamping, unclamping, and often blowing air to clear chips from the interface. You’ll typically see dedicated air line connections on these spindles.

- Critical Requirements: The pneumatic system is key. ATC spindles demand a high-pressure, stable, and exceptionally dry compressed air supply. Any moisture introduced via the air lines can quickly lead to corrosion and malfunction of the precise, high-tolerance internal parts, resulting in costly repairs.

- Performance Profile: ATC spindles are generally robust, high-power units (9 kW is a common benchmark, but many variations exist) designed for high-speed cutting.

- Best Use Cases: Ideal for complex jobs requiring multiple tools (e.g., different shapes for carving, different sizes for roughing and finishing passes) or for production environments where minimizing cycle time is crucial. They excel at processing harder sheet goods like MDF, particleboard, solid wood, and dense plywoods.

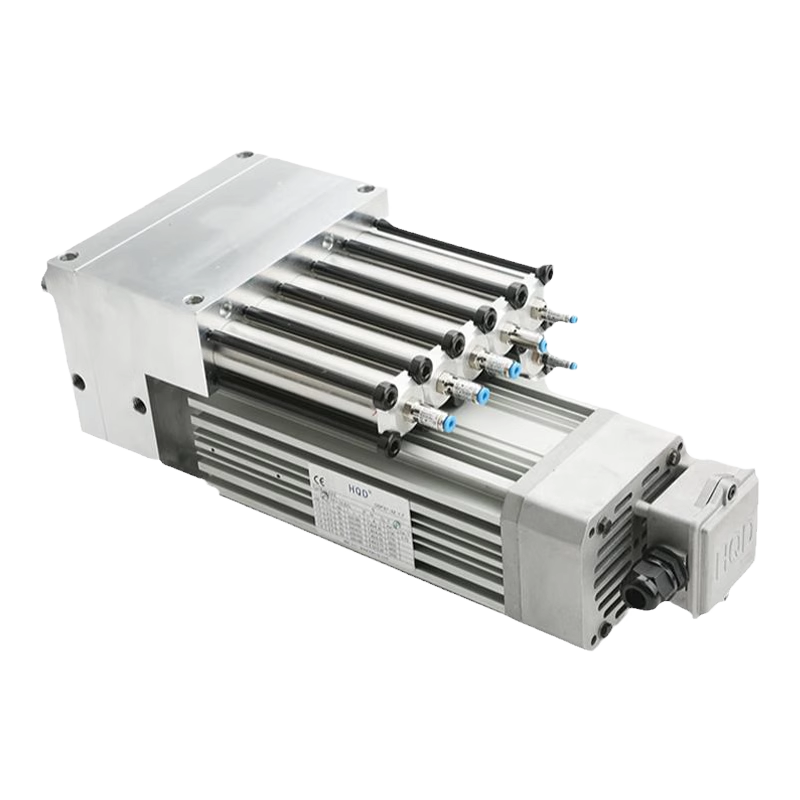

High-Efficiency Hole Making: Drilling Spindles / Drill Blocks

Specifically engineered for rapid drilling, these spindles are a common feature on machines used in cabinet making, furniture production, and other forms of panel processing.

- Structure & Function: Often referred to as a drill block or drill pack, this unit typically comprises a dedicated, lower-power motor driving a gearbox assembly that holds multiple drill bits in a fixed pattern (line or grid). This allows the machine to drill several holes simultaneously or in very quick succession with a single downward motion of the Z-axis.

- Efficiency Advantage: The ability to drill multiple holes at once provides a massive speed advantage for tasks like creating patterns for shelf pins, dowels, or system hardware compared to drilling each hole individually with a standard spindle.

- Performance & Limitations: These units typically operate at lower speeds (around 4,000 – 6,000 RPM) and have lower power ratings (e.g., 2 kW) than main cutting spindles. This specialization means they are strictly designed for drilling only and lack the power, speed, and bearing structure for routing, cutting, or surfacing operations.

- Key Requirements: The mechanical components within the drill block require regular maintenance, including lubrication (oiling) as per manufacturer specifications. Similar to ATC spindles, they rely on a stable, high-pressure air supply for consistent and accurate actuation of the drill strokes. In some setups, a secondary air pressure booster might be needed to guarantee optimal performance.

Choosing Advanced Spindles

ATC and Drilling Spindles cater to specific needs – automation and multi-tool flexibility for ATC, and sheer drilling speed for drill blocks. Understanding their capabilities, requirements (especially regarding air quality and maintenance), and limitations is vital when configuring or choosing a CNC router for demanding applications.

Next up in our series: Essential Daily Maintenance Tips to keep all types of spindles running smoothly!

More Posts

Get A Free Quote

Related Products

HALOONG CNC Cylindrical Shaft Polishing Machine

Dual Station Table Linear ATC CNC Wood Router: Automatic Tool Changer Wood CNC for Furniture Making

Why the HALOONG 12-Tool ATC CNC Wood Router Stands Out

The HALOONG 12-Tool ATC CNC Wood Router is a high-performance wood CNC machine built for exceptional efficiency and flexibility. Its automatic tool changer (ATC) switches between 12 tools in under 5 seconds, drastically reducing downtime and boosting output. Whether you’re cutting MDF, carving solid wood, or crafting intricate designs, this CNC wood router handles it all with ease. For even greater productivity, consider our optional dual-table configuration, which allows for near-continuous operation and significantly increases throughput for demanding production schedules.

Key Features of This CNC Wood Router

Here’s what makes this wood CNC a must-have:

Ultra-Fast Tool Switching

- 12-tool linear magazine: Holds a variety of tools, ready for instant use.

- Tool changes in under 5 seconds: The gantry-integrated design cuts travel time, keeping your production moving.

Versatile Material Processing

- Works with MDF, solid wood, OSB, PVC, acrylic, aluminum, and composite panels.

- Supports standard furniture joints (e.g., dowels and cams) and modern invisible connectors (e.g., Lamello, Peanut, Lockdowel).

- Perfect for cabinets, wardrobes, doors, and artistic carvings.

Customizable Worktable Options

- Options like 4'x8' (1220x2440 mm), 4'x9' (1220x2800 mm), or custom sizes available for single-table models.

- Maximize your output with our optional dual-table configuration, allowing for continuous loading and unloading on separate work zones.

- Upgraded vacuum table locks materials securely for flawless results on both single and dual-table setups.

Effortless Operation

- User-friendly controls with a clear display, network, and USB connectivity.

- Simplified design means even beginners can master it quickly. The dual-table operation is also intuitively managed through the advanced control system.

Built to Last with Precision

- Heavy-duty steel frame and high-precision gearbox for durability.

- Servo-driven system ensures smooth, accurate cuts every time. The robust construction ensures stability even during continuous operation on the dual-table model.

Cleaner, Safer Workspace

- Integrated dust collection and air-blow system keeps debris in check.

- Ideal for continuous, high-output runs without mess, making it perfect for the increased production demands of the dual-table system.

Top-Notch Support

- Free technical support, lifetime service, and remote assistance included.

PUR Glue Machine Kit For Edge Bander

Four-Spindle Dual-Station CNC Wood Router for Panel Furniture Manufactured

Maximize your panel furniture manufacturing throughput with the HALOONG Four-Spindle Dual-Station CNC Router. Expanding on the reliability of our single-station four-spindle CNC wood cutting machines, this dual-station system provides a substantial increase in production efficiency. It's designed for continuous operation, minimizing downtime and maximizing output through its smart workflow.

The clever dual-station workbench facilitates seamless alternating work cycles. While one station is engaged in machining, the operator can efficiently prepare the next batch of materials on the adjacent station. Upon completion of the first cycle, the machine instantly transitions to the pre-loaded second station. This continuous processing approach ensures no wasted time, making it a key asset for high-volume furniture production.