HALOONG CNC High Precision CNC Router & Smart Panel Furniture Production Line Solution

Home / Furniture CNC

High Precision CNC Router & Smart Panel Furniture Production Line Solution

Complete The Form To Request A Quote Today!

Furniture CNC Machines

Whether you are a furniture manufacturer, a cabinet customization workshop, or a metal processing company, HALOONG CNC provides you with a full range of reliable intelligent equipment, including economical CNC routers, 5-axis industrial engraving machines, panel furniture intelligent production lines and customized production line integration solutions. HALOONG CNC provides reliable and cost-effective woodworking CNC routers for users from all over the world, including the United States, Italy, Vietnam, Kazakhstan, India, Russia, etc. These machines can process cabinets, wardrobes, office furniture, customized home furnishings, and interior decorations. To get a quote or learn about CNC machine parameters, you can contact us, we provide you with 24/7 service.

smart factory lines

The intelligent production line of panel furniture is equipped with intelligent cutting: HALOONG nested CNC cutting machine, which optimizes the utilization rate of panels to 90%+. Efficient edge banding: fully automatic linear edge banding machine, speed 20m/min, supports pre-milling & tracking chamfering. Precision drilling: six-sided drilling/side drilling center, hole position accuracy ±0.1mm, supports 32mm system customization. Surface treatment: vacuum laminating machine, supports PVC, veneer, fireproof board and other materials. Applicable products: cabinets, wardrobes, office furniture, customized home furnishings, interior decoration parts.

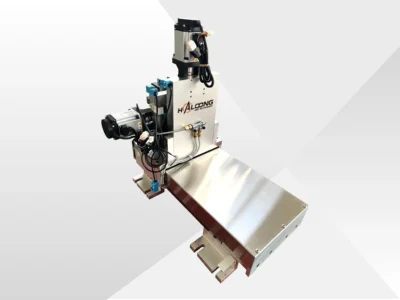

HALOONG PUR Dual-Color Gluer Retrofit Kit

Magnetic Levitation Edge Banding Machine Synchronous Side Drilling Kit

Electric Scissor Hydraulic Lifting Machine

PUR Glue Machine Kit For Edge Bander

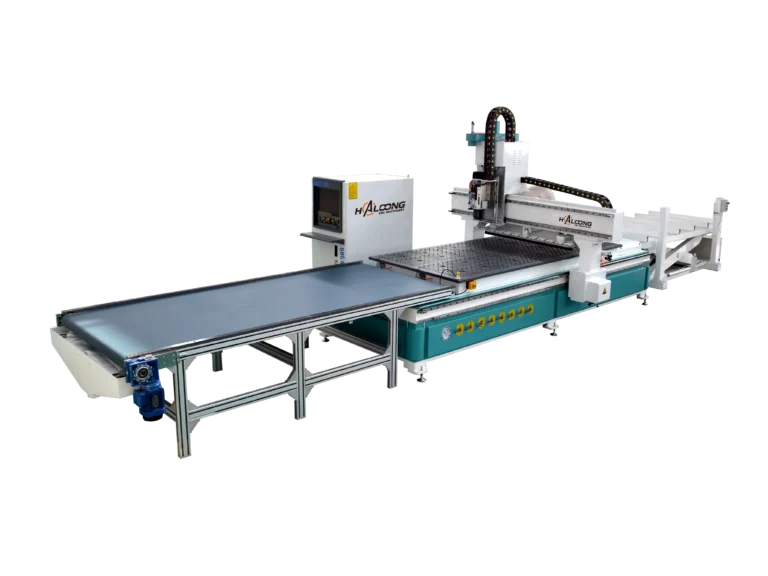

HALOONG Automatic Loading and Unloading CNC Cutting Furniture Production Line

nesting CNC

HALOONG nesting CNC router series has standard table sizes: 2x2 feet (24 inches x 24 inches), 2x3 feet (24 inches x 36 inches), 2x4 feet (24 inches x 48 inches), 4x4 feet (48 inches x 48 inches), 4x8 feet (48 inches x 96 inches), 5x10 feet (60 inches x 120 inches), 6x12 feet (72 inches x 144 inches), etc., support non-standard customization, suitable for furniture carving and composite material cutting. Intelligent operating system: compatible with CAD/CAM software, and other software, Multi-material compatible: wood, acrylic, PVC, etc., to meet diversified production needs.

Best Linear Automatic Tool Changer CNC Router for Woodworking – Precision & Power

The Nesting CNC for Woodworking Router is a premium, multi-process solution engineered for workshops, cabinet shops, and custom furniture makers. Combining high-speed cutting, automated tool changes, and smart nesting software, this machine excels at precision milling, drilling, grooving, and 3D carving of hardwoods, plywood, and composites. Built for heavy-duty production with safety and energy-efficient design, it’s ideal for crafting cabinets, architectural millwork, and bespoke furniture.

CNC Wood Router With Four-Spindle: Precision & Power for Furniture

Key Features and Benefits of Four-Spindle CNC Wood Router

Multi-Spindle Productivity This CNC wood router comes with four independent spindles, allowing simultaneous use of multiple tools—such as milling cutters and drill bits—with tool switches in just 2 seconds. Perfect for high-volume production, it cuts downtime and maximizes output.

Hardwood Mastery Powered by a 7.5kW spindle motor, this CNC wood router tackles tough hardwoods effortlessly. It drills precise holes for furniture connectors like Cam Fittings and Pre-inserted Plastic Nuts, mills slots for back panels, and carves intricate cabinet designs with consistent quality.

Easy-to-Use Design Built for all skill levels, this CNC wood router features an intuitive control panel with knobs, a reset button, and an emergency stop. Network and USB connectivity simplify file transfers, while pop-up locating pins ensure fast, accurate material setup.

Customizable Worktable The vacuum adsorption worktable keeps panels secure, minimizing errors. Available in sizes like 4'x8' (1220x2440 mm), 5'x10' (1525x3050 mm), 5'x12' (1525x3660 mm), or 6'x12' (1830x3660 mm), this CNC wood router adapts to your needs with custom options.

Precision and Durability Constructed with a heavy-duty square steel frame, a high-precision gearbox, and a servo system, this CNC wood router ensures lasting reliability and exceptional accuracy—ideal for continuous, demanding workloads.

Clean and Safe Operation An integrated cutting, blowing, and dust collection system reduces debris, maintaining a tidy and healthy workspace, a must-have for modern CNC wood router users.

Dual Station Table Linear ATC CNC Wood Router: Automatic Tool Changer Wood CNC for Furniture Making

Why the HALOONG 12-Tool ATC CNC Wood Router Stands Out

The HALOONG 12-Tool ATC CNC Wood Router is a high-performance wood CNC machine built for exceptional efficiency and flexibility. Its automatic tool changer (ATC) switches between 12 tools in under 5 seconds, drastically reducing downtime and boosting output. Whether you’re cutting MDF, carving solid wood, or crafting intricate designs, this CNC wood router handles it all with ease. For even greater productivity, consider our optional dual-table configuration, which allows for near-continuous operation and significantly increases throughput for demanding production schedules.

Key Features of This CNC Wood Router

Here’s what makes this wood CNC a must-have:

Ultra-Fast Tool Switching

- 12-tool linear magazine: Holds a variety of tools, ready for instant use.

- Tool changes in under 5 seconds: The gantry-integrated design cuts travel time, keeping your production moving.

Versatile Material Processing

- Works with MDF, solid wood, OSB, PVC, acrylic, aluminum, and composite panels.

- Supports standard furniture joints (e.g., dowels and cams) and modern invisible connectors (e.g., Lamello, Peanut, Lockdowel).

- Perfect for cabinets, wardrobes, doors, and artistic carvings.

Customizable Worktable Options

- Options like 4'x8' (1220x2440 mm), 4'x9' (1220x2800 mm), or custom sizes available for single-table models.

- Maximize your output with our optional dual-table configuration, allowing for continuous loading and unloading on separate work zones.

- Upgraded vacuum table locks materials securely for flawless results on both single and dual-table setups.

Effortless Operation

- User-friendly controls with a clear display, network, and USB connectivity.

- Simplified design means even beginners can master it quickly. The dual-table operation is also intuitively managed through the advanced control system.

Built to Last with Precision

- Heavy-duty steel frame and high-precision gearbox for durability.

- Servo-driven system ensures smooth, accurate cuts every time. The robust construction ensures stability even during continuous operation on the dual-table model.

Cleaner, Safer Workspace

- Integrated dust collection and air-blow system keeps debris in check.

- Ideal for continuous, high-output runs without mess, making it perfect for the increased production demands of the dual-table system.

Top-Notch Support

- Free technical support, lifetime service, and remote assistance included.

CNC Engraving Machine Center with Carousel Automatic Tool Changer

Industrial-Grade CNC Router: High-Performance Solution for Modern Manufacturing

Four-Spindle Dual-Station CNC Wood Router for Panel Furniture Manufactured

Maximize your panel furniture manufacturing throughput with the HALOONG Four-Spindle Dual-Station CNC Router. Expanding on the reliability of our single-station four-spindle CNC wood cutting machines, this dual-station system provides a substantial increase in production efficiency. It's designed for continuous operation, minimizing downtime and maximizing output through its smart workflow.

The clever dual-station workbench facilitates seamless alternating work cycles. While one station is engaged in machining, the operator can efficiently prepare the next batch of materials on the adjacent station. Upon completion of the first cycle, the machine instantly transitions to the pre-loaded second station. This continuous processing approach ensures no wasted time, making it a key asset for high-volume furniture production.

Ready To Experience HALOONG Furniture CNC ?

Complete The Form To Request A Quote Today!

CNC drilling

As the core equipment for modern panel furniture production, HALOONG intelligent CNC drilling machine uses vertical, horizontal and lateral multi-axis linkage technology to accurately realize punching, drilling, slotting and complex angle processing, fully adapting to the mass production needs of customized furniture such as cabinets, wardrobes, and display racks. Multi-function integration: A single machine completes drilling, milling, chamfering and other processes, supporting 32mm system standard hole positions and personalized design. Multi-angle processing: Equipped with 90° side drill bit and 360° rotating axis, it can easily cope with the six-sided drilling and special-shaped parts processing of the panel. Production line collaboration: Seamlessly connect CNC cutting machines, edge banding machines and other equipment to build an intelligent furniture production line, reducing labor dependence by more than 30%. Panel furniture: Drilling and pre-embedding of hardware for MDF, particleboard, and plywood cabinets. Customized production: Precision processing of cabinet door panel ventilation holes, wardrobe layer adjustment holes, display rack connection holes, etc.

Magnetic Levitation Edge Banding Machine Synchronous Side Drilling Kit

CNC Dual Spindle Side Slotting and Drilling Machine

CNC Six Sided Drilling Machine

CNC Side Drilling Machine

edge bander

PUR glue machines offer unmatched durability and precision for industrial applications. Tailored for woodworking, furniture assembly, and more in North America and Europe, this machine outperforms traditional options with its innovative design and strong bonding capabilities. Unmatched Bond Strength: Moisture-curing PUR adhesives in hot and humid environments ensure a permanent, high-strength bond. The flexibility of PUR solutions over laser edgebanding allows for easy bonding of wood, textiles, and composites. Environmental efficiency outperforms EVA's high waste volume. High-speed precision: Adjustable settings surpass the fixed settings of lasers to maximize output without compromising quality. Main applications Woodworking, furniture manufacturing, textile industry, building materials.

HALOONG PUR Dual-Color Gluer Retrofit Kit

Magnetic Levitation Edge Banding Machine Synchronous Side Drilling Kit

PUR Glue Machine Kit For Edge Bander

vacuum press machine

Take your woodworking to the next level with the Vacuum Hot Press Wood Bender, the leading automated vacuum wood bender that delivers perfect precision in bending wood. The uniform heat and vacuum pressure of this vacuum hot press wood bender ensures stable, accurate bending, and high-frequency heating cures glue and shapes wood in minutes. Hot press woodworking equipment goes beyond traditional methods. Great for furniture and decoration, it's ideal for craftsmen and manufacturers, replacing slow manual wood bending with a fast, reliable, smart hot press solution that improves productivity and quality. Main applications in furniture manufacturing: Great for making curved chair backs, table edges, and bed frames. Woodworking: Shape MDF, plywood, and solid wood into curved shapes. Interior design: Great for custom curved panels and decoration. Featured products: Make musical instrument parts and arched structures.