Custom Panel Furniture Manufacturing Process and Workflow

Custom panel furniture is popular for its design flexibility, efficient space use, and diverse finishes. Producing this furniture involves precise, interconnected steps, heavily relying on advanced machinery and manufacturing management. Understanding the custom panel furniture manufacturing process helps appreciate the quality and timeline of bespoke pieces. Indeed, modern technology, like automation and CNC equipment, significantly boosts production efficiency and precision in panel furniture production.

Stage 1: Design and Confirmation for Custom Panel Furniture

The furniture manufacturing process starts with design and close client communication. First, designers consult clients on needs, habits, style, and budget. They then perform precise on-site measurements for detailed data. Second, designers use professional software (e.g., Cabinet Vision, CAD) to create layouts, structures, functions, select panels/hardware, and match colors/styles. They carefully consider ergonomics and stability. Third, design completion leads to visual renderings for preview. After client approval, we generate detailed shop drawings, part lists, hardware lists, and CNC files (dimensions, cuts, drills, edge banding). Finally, clients approve the design, drawings, materials, and quotes. Both parties sign contracts detailing product specifics and timelines for their custom panel furniture.

Stage 2: Preparation for Panel Furniture Production

After design confirmation, the factory prepares for production. Primarily, we break down orders into tasks detailing panel types, quantities, and parts. The production planning department then schedules tasks based on priority, capacity, and stock. Next, based on the schedule, we buy materials like panels (particleboard, MDF, plywood), edge banding, hardware, and other items. We inspect materials upon arrival. Furthermore, we import CNC processing data from design into production systems. Nesting software optimizes part layout on panels, minimizing waste and preparing for efficient panel processing.

Stage 3: Precision Panel Processing

This is the core of panel furniture production, where automated CNC machinery plays a vital role.

Cutting and Sawing: Precision with HALOONG CNC Routers

Using CAD/CAM software to nest by size can make CNC machining more material-efficient

Using optimized plans, we precisely cut panels into parts with saws or automated electronic cutting saws. Automated machines read electronic files for feeding, positioning, and cutting. Specifically, our HALOONG CNC routers excel at precise cutting and nesting, boosting material yield and cutting costs in custom panel furniture making.

Edge Banding: Enhancing Durability and Aesthetics

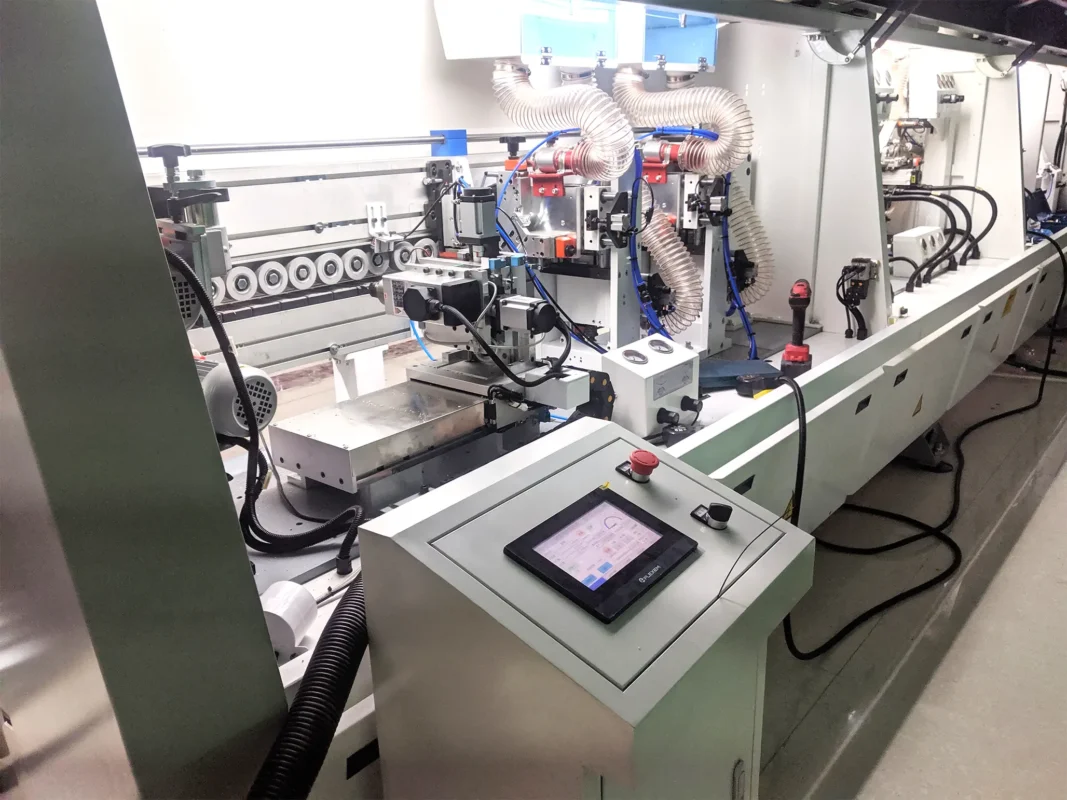

Cut panel edges need sealing to improve looks, prevent moisture damage, and limit off-gassing. Edge banders apply tape using hot melt glue. Modern machines offer integrated trimming and finishing. To enhance the edge banding process, we offer HALOONG edge banding machine upgrade kits, like the PUR two-color glue kit, for better sealing and moisture resistance.

Drilling: Efficient Hole Processing with HALOONG Machines

side drilling kit for edge bander

Drilling machines or CNC machining centers create holes for connectors and hardware. CNC allows complex hole patterns and milling in one step. For efficient panel processing, HALOONG provides CNC side drilling machines and CNC six-sided drilling machines for accurate hole drilling. Additionally, our magnetic levitation synchronous side drilling kit integrates with edge banders for simultaneous processing, further increasing efficiency.

Routing and Grooving: Complex Shapes with CNC Machining Centers

HALOONG CNC is carving cabinet doors

Routers or CNC machining centers shape parts, create grooves, or handle irregular designs (e.g., door profiles). Our HALOONG automatic tool change CNC machining centers offer simple operation for complex carving and milling tasks, expanding design possibilities for custom panel furniture.

Stage 4: Assembly of Furniture Components

Processed parts move to assembly after panel processing. Sometimes, simple units may be pre-assembled, or parts go straight to packaging for on-site assembly. Custom furniture often involves factory processing and packaging for later home assembly. Before assembly, hardware is checked against the list, ensuring everything is ready.

Stage 5: Quality Control in Furniture Manufacturing

Quality control happens throughout production to ensure product standards. Firstly, we check raw materials like panels and hardware for quality. Secondly, we perform spot checks or full inspections after key steps (cutting, edge banding, drilling) to verify dimensions, edge sealing, and hole accuracy. Thirdly, we inspect finished parts for appearance, structure, function, dimensions, and finish. All parts must be present and processed correctly. Finally, a visual check before packaging ensures good product condition.

Stage 6: Packaging for Custom Orders

A packer is packing furniture parts using HALOONG sorting & packing software

Approved parts are carefully packed for transport and protection. We clean parts and protect vulnerable spots. Then, we sort parts for the same cabinet or area and pack them using foam, cardboard, etc. Labels identify the contents and destination for easy installation. To boost packaging accuracy and speed, HALOONG offers sorting and packaging software. Workers scan part barcodes or QR codes for guided sorting and packing, effectively preventing missing or incorrect parts.

We also count, sort, and pack hardware, usually with instructions.

Stage 7: Warehousing and Logistics

Packed products await shipment in the warehouse. We scan packed products into inventory, recording details for shipping. Logistics then transports products to the client’s address based on the delivery date. Careful handling prevents damage during transit.

Stage 8: On-site Installation

Professional installers complete the final step at the client’s home. The application of sorting and packaging software simplifies this by ensuring all parts are present and easy to identify. Installers and clients first check the delivered items against the list. Then, workers assemble furniture using instructions and tools. After the main assembly, cabinets are leveled, fixed to the walls, and the site is cleaned. Finally, clients inspect the completed custom panel furniture, confirming correctness and function.

Conclusion

haloong atc cnc wood router with automatic unloading platform and automatic scissor lift for loading

Manufacturing custom panel furniture is a complex process from design to installation. Automation and smart equipment significantly improve efficiency and quality. Using high-precision, cost-effective industrial HALOONG CNC equipment boosts factory efficiency and automation levels. HALOONG provides CNC routers for cutting, ATC machining centers for complex tasks, and CNC drilling machines (side and six-sided) for drilling. Our edge bander kits enhance edge banding, and our sorting/packaging software prevents errors, aiding on-site assembly. These HALOONG solutions optimize factory operations. We also offer hydraulic lifts, automated lines, and customized industrial CNC equipment, supporting factories in their smart transformation. Precise execution and quality control at each stage ensure high-quality custom panel furniture.

Related Products

HALOONG CNC Cylindrical Shaft Polishing Machine

Dual Station Table Linear ATC CNC Wood Router: Automatic Tool Changer Wood CNC for Furniture Making

Why the HALOONG 12-Tool ATC CNC Wood Router Stands Out

The HALOONG 12-Tool ATC CNC Wood Router is a high-performance wood CNC machine built for exceptional efficiency and flexibility. Its automatic tool changer (ATC) switches between 12 tools in under 5 seconds, drastically reducing downtime and boosting output. Whether you’re cutting MDF, carving solid wood, or crafting intricate designs, this CNC wood router handles it all with ease. For even greater productivity, consider our optional dual-table configuration, which allows for near-continuous operation and significantly increases throughput for demanding production schedules.

Key Features of This CNC Wood Router

Here’s what makes this wood CNC a must-have:

Ultra-Fast Tool Switching

- 12-tool linear magazine: Holds a variety of tools, ready for instant use.

- Tool changes in under 5 seconds: The gantry-integrated design cuts travel time, keeping your production moving.

Versatile Material Processing

- Works with MDF, solid wood, OSB, PVC, acrylic, aluminum, and composite panels.

- Supports standard furniture joints (e.g., dowels and cams) and modern invisible connectors (e.g., Lamello, Peanut, Lockdowel).

- Perfect for cabinets, wardrobes, doors, and artistic carvings.

Customizable Worktable Options

- Options like 4'x8' (1220x2440 mm), 4'x9' (1220x2800 mm), or custom sizes available for single-table models.

- Maximize your output with our optional dual-table configuration, allowing for continuous loading and unloading on separate work zones.

- Upgraded vacuum table locks materials securely for flawless results on both single and dual-table setups.

Effortless Operation

- User-friendly controls with a clear display, network, and USB connectivity.

- Simplified design means even beginners can master it quickly. The dual-table operation is also intuitively managed through the advanced control system.

Built to Last with Precision

- Heavy-duty steel frame and high-precision gearbox for durability.

- Servo-driven system ensures smooth, accurate cuts every time. The robust construction ensures stability even during continuous operation on the dual-table model.

Cleaner, Safer Workspace

- Integrated dust collection and air-blow system keeps debris in check.

- Ideal for continuous, high-output runs without mess, making it perfect for the increased production demands of the dual-table system.

Top-Notch Support

- Free technical support, lifetime service, and remote assistance included.

PUR Glue Machine Kit For Edge Bander

Four-Spindle Dual-Station CNC Wood Router for Panel Furniture Manufactured

Maximize your panel furniture manufacturing throughput with the HALOONG Four-Spindle Dual-Station CNC Router. Expanding on the reliability of our single-station four-spindle CNC wood cutting machines, this dual-station system provides a substantial increase in production efficiency. It's designed for continuous operation, minimizing downtime and maximizing output through its smart workflow.

The clever dual-station workbench facilitates seamless alternating work cycles. While one station is engaged in machining, the operator can efficiently prepare the next batch of materials on the adjacent station. Upon completion of the first cycle, the machine instantly transitions to the pre-loaded second station. This continuous processing approach ensures no wasted time, making it a key asset for high-volume furniture production.