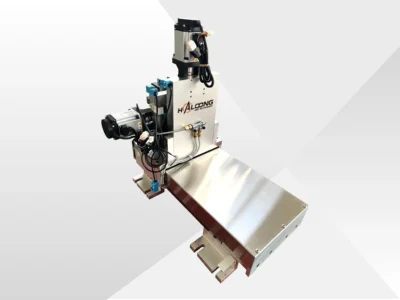

Unlock the Potential of CNC Machinery

Across Diverse Industrial Applications

Home / Industry Applications

CNC Router Multiple Applications

for Wide Range of Industries

When you consider buying a CNC machine, you will think: What problems can this equipment solve for my factory? In fact, whether it is making furniture, carved wood trim, metal parts or plastic molds, CNC machines can automatically complete precise processing, easily complete complex processing such as cutting, engraving, drilling, etc., and turn the design into a physical object.

CNC routers have become the core driving force of modern manufacturing, with the characteristics of high precision, high repeatability, and high efficiency. They are widely used in furniture manufacturing, aviation and automobile industries, advertising logos, electronic communications, construction woodworking, medical equipment, packaging and printing, new energy, shipping, artistic creation, and personalized customization.

PS:Here is also a concise guide to help you choose our CNC.

Whether you are a craft enthusiast, a small or medium-sized business owner, or even an industrial giant, you can use CNC machines to realize your ideas and goals. The following are the application scenarios of CNC machines in different fields:

Wood Products

HALOONG CNC routers enable architects and woodworkers to easily realize complex and precise designs,It excel at making cabinets, wardrobes, dining tables, headboards, office furniture, complex carvings, inlays and decorative, mass production of panel furniture.

Kitchen & Bath

Applications of HALOONG CNC routers in the kitchen and bath industry:

• Cabinet Processing: Cutting cabinet panels made of wood or composite materials.

• Countertop Shaping: Machining edges of artificial stone or solid wood countertops.

• Decorative Element Engraving: Engraving patterns on kitchen and bathroom door panels.

New Energy Industry

Applications of HALOONG CNC Routers in the new energy industry:

• Wind Turbine Blade Models: Creating blade prototypes for wind tunnel testing.

• Solar Panel Bracket Processing: Cutting metal or plastic bracket components.

• Battery Enclosure Forming: Machining lightweight battery housings.

Musical Instrument Manufacturing

Applications of HALOONG CNC routers in musical instrument manufacturing:

• Guitar Body Processing: Cutting the body shape and carving the sound hole.

• Violin Component Making: Machining components such as the top and back plates, and the neck.

• Percussion Instrument Parts: Precision shaping of parts like drum shells and xylophone keys.

Advertising and Signage Industry

Applications of HALOONG CNC routers in the advertising and signage industry:

• 3D Lettering Production: Cutting metal, acrylic, or wood to create three-dimensional advertising letters.

• Signage Processing: Producing storefront signs, road signs, and display boards.

• Display Stand Forming: Machining display structures for exhibitions.

Furniture Manufacturing

Applications of HALOONG CNC routers in furniture manufacturing:

• Component Cutting: Processing furniture parts such as table legs and chair backs.

• Decorative Engraving: Engraving patterns or designs on furniture surfaces.

• Assembly Prototyping: Creating prototypes of furniture designs.

Get expert recommendations for your industrial CNC needs

Complete The Form To Request A Quote Today!

Metal Processing

Applications of HALOONG CNC Routers in metal processing:

• Light Metal Cutting: Machining light metal plates such as aluminum and copper.

• Engraving and Marking: Engraving patterns or markings on metal surfaces.

• Prototype Production: Creating metal prototypes of mechanical parts or decorative pieces.

Shipbuilding Industry

Applications of HALOONG CNC Routers in the shipbuilding industry:

• Hull Model Making: Machining small-scale hull prototypes or testing models.

• Deck Component Processing: Cutting wood or composite materials to create deck decorative pieces.

• Interior Decoration Engraving: Engraving patterns or structures on wooden interiors.

Mold Making

Applications of HALOONG CNC routers in mold making:

• Plastic Molds: Machining prototypes or small-scale molds for injection molding.

• Metal Molds: Engraving mold components made of light metals (such as aluminum).

• Prototype Molds: Creating test molds for product development.

Toy Manufacturing

Applications of HALOONG CNC Routers in toy manufacturing:

• Wooden Puzzles: Cutting intricate puzzle shapes.

• Plastic Toy Components: Machining parts for toy cars, building blocks, etc.

• Model Making: Producing model toys such as airplanes and trains.

Stage and Film Props

Applications of HALOONG CNC Routers in stage and film props:

• Theater Props: Creating realistic furniture and weapon models.

• Movie Sets: Machining architectural models and background decorations.

• Large-scale Installation Art: Cutting wood or foam to create art installations.

Handicraft Production

Applications of HALOONG CNC routers in handicraft production:

• Artwork Engraving: Engraving reliefs and sculptures on wood, stone, or metal.

• Model Making: Producing architectural models, ship models, etc.

• Personalized Decoration: Creating customized ornaments and souvenirs.

Jewelry and Handicraft

HALOONG CNC routers are primarily used in jewelry and handicraft manufacturing for:

• Jewelry Mold Engraving: Creating molds for rings, necklaces, earrings, etc.

• Complex Pattern Processing: Engraving intricate patterns on precious metals, wood, or jade.

• Small Handicraft Production: Such as reliefs, medals, and decorative ornaments.

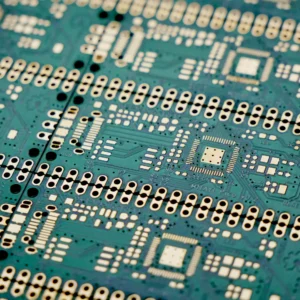

Electronics Industry

Applications of HALOONG CNC routers in the electronics industry:

• PCB Cutting: Cutting or drilling printed circuit boards (PCBs).

• Electronic Enclosure Processing: Manufacturing plastic or metal enclosures (such as mobile phone cases and equipment housings).

• Parts Prototyping: Producing prototypes of small electronic components.