Why Choose Us - HALOONG Machine Tools Manufacturer Co.,Ltd (Zhengzhou)

HALOONG CNC is your trusted partner in the CNC industry

Reliability and performance over 45 years

Solid technical foundation:

inheritance and innovation

Our R&D team is led by engineers with more than 20 years of experience, integrating mechanical design principles with digital simulation technology.

① Senior engineers with more than 20 years of experience lead the mechanical structure design to ensure the reliability of the classic transmission system

② The Mesozoic team uses modern CAD/CAE integrated simulation development technology to detect more than 90% of design defects in advance, 100% digital preview of motion trajectory, and eliminate the risk of mechanical motion interference in advance

③ The R&D and after-sales engineering teams work closely together to continuously improve the process and evolve the technology, adapt to the latest industry processes, and dynamically adjust the processing parameter library to adapt to a variety of new composite materials.

Visible quality control:

a transparent and traceable manufacturing system

1. Optimize supply chain management

Our long-term international partners for core components include: guide rails/screws: Taiwan PMI/Japan THK; spindles: Italy HSD; control systems: Taiwan Syntec/LNC; motion components: Japan Yaskawa/Japan Shimpo. We also have leading companies in the field from China, such as HQD, Inovance, Xinje, Schneider, etc., who also have reliable performance and quality.

2. Independent processing of core structure

Our factory has several large CNC five-axis gantry milling machines and lathes, drilling machines, grinders and other mother machines, and the engineers who use them are experienced.

① The CNC five-axis gantry milling machine performs fine processing on the machine body rack, guide rails, processing planes, etc. to ensure basic accuracy

② CNC lathes, drilling machines, etc. are used to fine-process important auxiliary parts to ensure the matching accuracy between important parts.

3. Precision assembly quality commitment

① Single-person responsibility system assembly: Each device is led by the same engineer throughout the entire process to reduce the accumulation of collaborative errors

②Precision tool matching: For fixed parts with high requirements, use torque wrenches to tighten according to the manufacturer's recommendations to ensure that the parts meet the design requirements

4. Reliable accuracy standards

Before each machine leaves the factory, we will conduct a two-stage precision calibration:

① Laser interferometer coarse adjustment (±0.01mm)

② Micrometer micrometer manual fine adjustment (final error ≤ 0.05mm)

5. Visualization of quality inspection process

①. Raw material inspection→ ②. Rough machining of fuselage→ ③. Five-axis precision milling→ ④. Component assembly→ ⑤. Single-person full assembly→ ⑥. Two-stage precision calibration→⑦. Load test → ⑧. Customer on-site acceptance

If you are not sure about the manufacturing process of the equipment you purchased, contact us and you can use remote video monitoring and on-site monitoring.

PS:Read this blog to get more relevant suggestions

Production Process Details

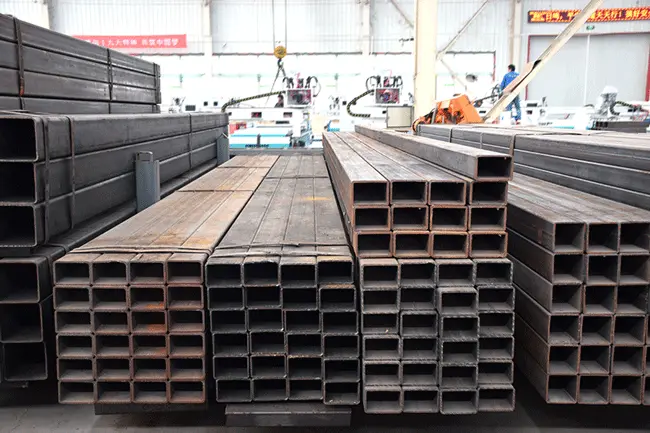

Heavy Raw Materials

Raw materials that meet industry standards and have been quality-tested

Reliable Basic Process

Heavy-duty body ensures the stability and precision of the equipment

Guaranteed Accuracy

Professional equipment finishing to ensure matching accuracy between parts

High-quality Accessories

Ensure stable performance and lifespan of the machine

Excellent Core Control System

Bringing a variety of processing programs and high performance

Precision Assembly

Professional engineers and equipment ensure high standards

Accuracy Calibration

Professional instruments calibrate the accuracy to ensure compliance with standards

Factory Inspection

Use real materials and processes to verify machine accuracy

Unique advantages of HALOONG CNC

Flexible Service Model

HALOONG CNC can provide pre-sales consultation according to your needs. You only need to contact us: ①Production line planning simulation, free Factory CAD plant layout suggestions ② Provide customers with cost-effective configuration solutions based on their budget. ③Process adaptation diagnosis: customize different equipment parameters and production processes according to the characteristics of the materials

Worry-free After-sales Service

Worry-free after-sales service ①You can contact us in many ways (such as phone, email, social media), tell us the fault of the equipment, and our engineering team will handle it for you quickly.②We can provide video diagnosis (establish connection within 4 hours), cross-border support of engineers, and free refresher training during the warranty period.

Commitment To High Cost Performance

① Thanks to China's supply chain advantages, our products are 30-50% cheaper than international brands, but can maintain the same accuracy and life; ②If you don’t want to buy a new machine, we can provide official renovation services for second-hand equipment at a small cost (the specific price depends on your requirements)

Commitments Of HALOONG CNC

Provide proven and reliable models

Ensure that the equipment life is ≥ 8 years

under normal maintenance conditions

Free industry solution library

covering solid wood furniture/board customization/art carving and other sub-sectors

Provide lifetime technical support

Ready For A Free Quote?

Fill out this brief form and a CNC specialist will be in touch to review the best machine and pricing for you.